selos WTPN

terminal blocks with

push-in connection

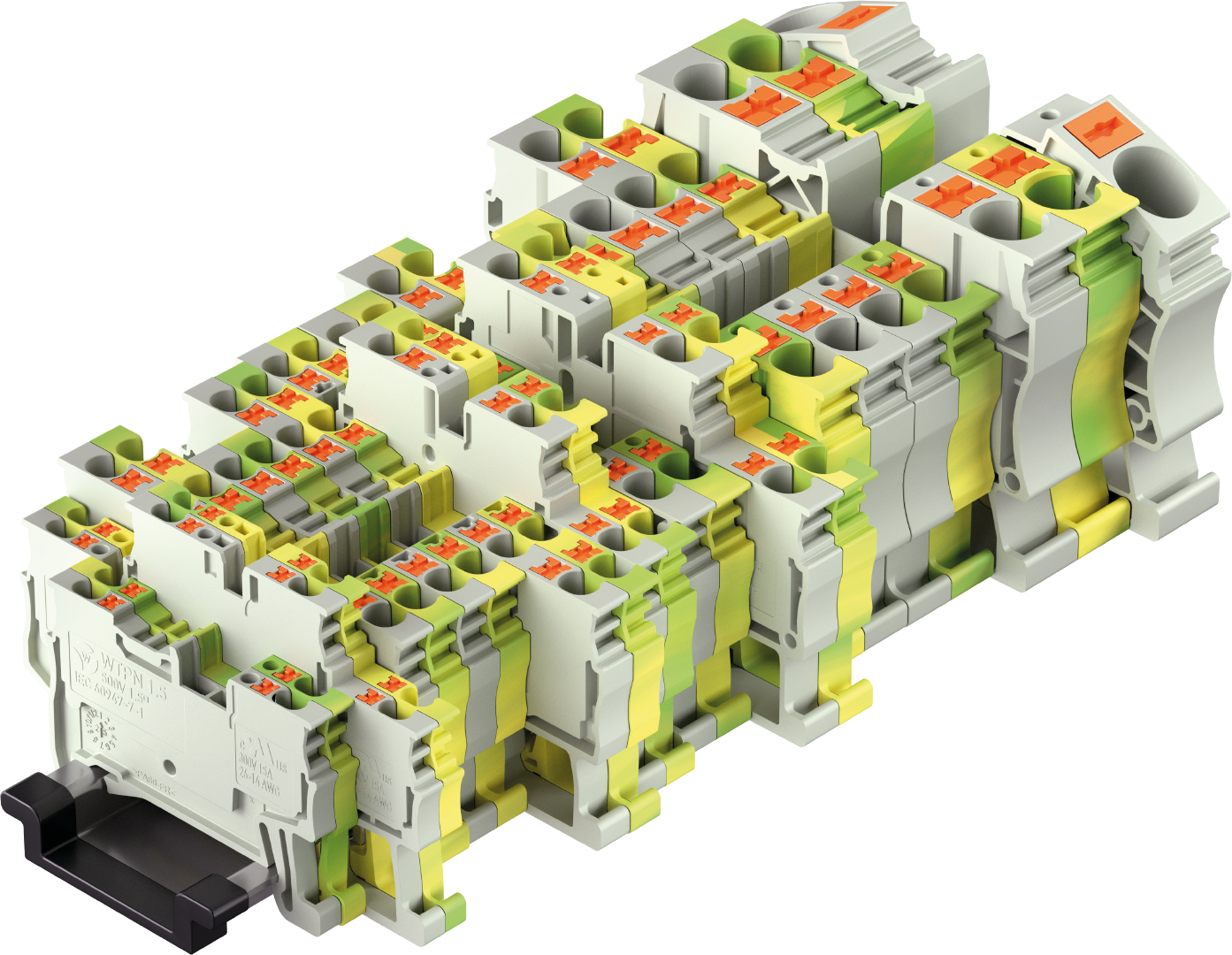

WTPN terminal blocks combine innovative push-in connection technology with a compact design, a high-performance contact system, and a well-thought-out overall concept.

EFFORTLESS, RELIABLE, AND FUTURE-PROOF POWER DISTRIBUTION – EVERYWHERE!

As an expert in terminal block technology, Wieland has made reliable connection technology part of its DNA. Now we are setting new standards with the WTPN terminal blocks for DIN rails by combining state-of-the-art PUSH-IN technology with intelligent product design.

The result: tool-free wiring, reduced installation time, and minimized inventory requirements. With vibration-proof, maintenance-free connections and high contact force, WTPN is ideal for low-voltage power distribution in demanding industrial environments.

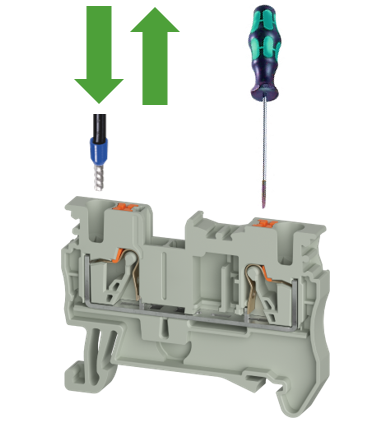

CONNECTION WITH OR WITHOUT TOOL

- Insert conductors with ferrule or solid conductors directly

- connection of fine-stranded conductors with a slotted or Phillips screwdriver

- Intuitive, vibration-proof conductor connection

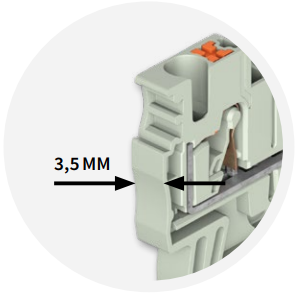

SPACE-SAVING

DESIGN

- High density at only 3.5 mm, rated for up to 300 V, 15 A, 14 AWG

- Multi-conductor and multi-tier terminal blocks with up to 66% space savings

- Dual-row bridging channels for easy connection (daisy chain)

INTEGRATED FUNCTIONS

- Integrated test point for troubleshooting and commissioning

- Integrated push button enables releasing all conductor types with a slotted or Phillips screwdriver

- Screwless, clip-on protective earth terminal blocks

selos WTPN

terminal blocks with

push-in connection

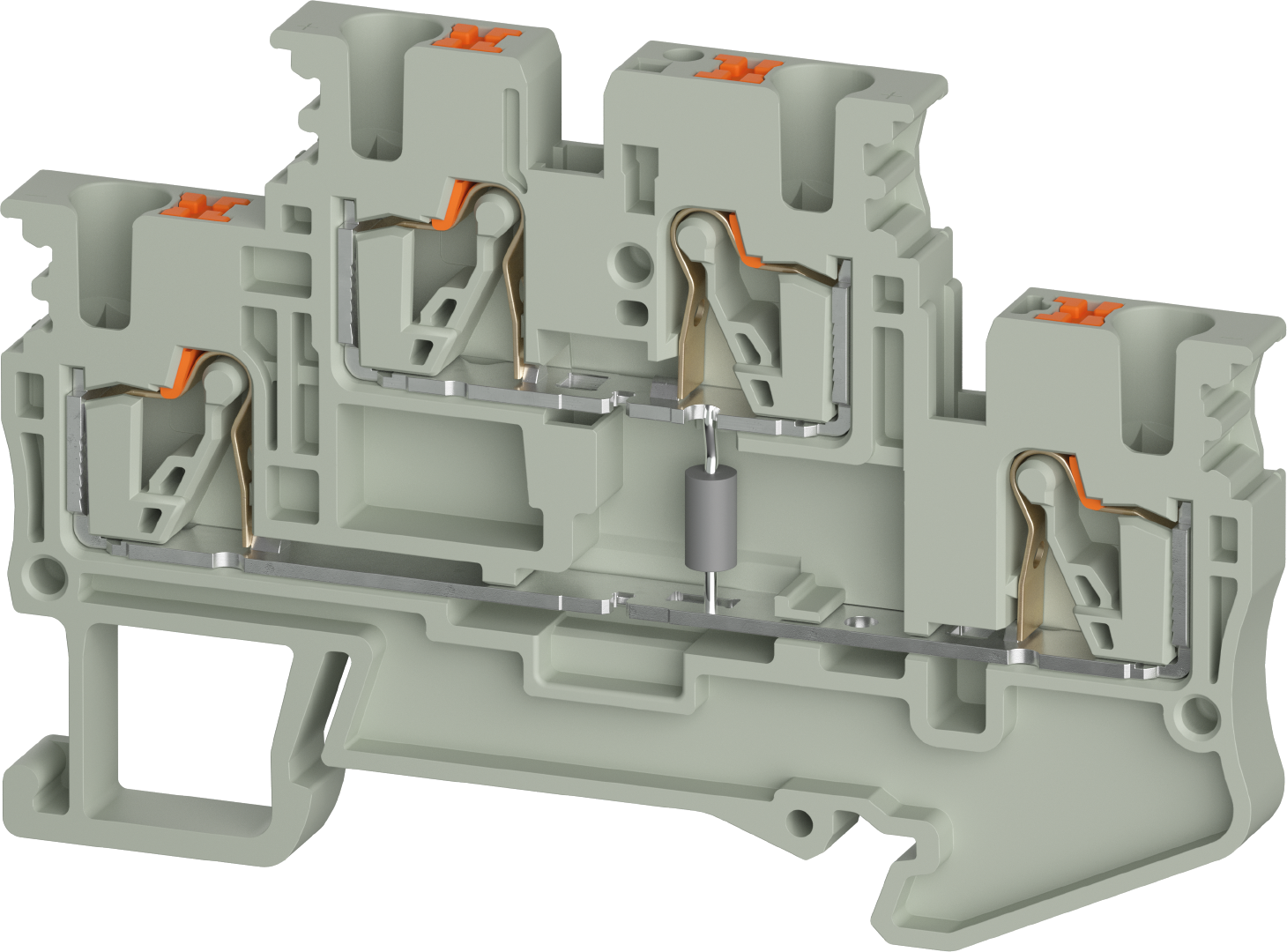

Effortless wiring – with or without tool! The selos WTPN terminal blocks feature intuitive PUSH-IN technology for fast, tool-free cable preparation. Solid conductors or conductors with ferrules can be inserted directly without tool. To further reduce installation time, the series offers pluggable bridges, continuous strip markers, planning and design software, labeling systems, and much more.

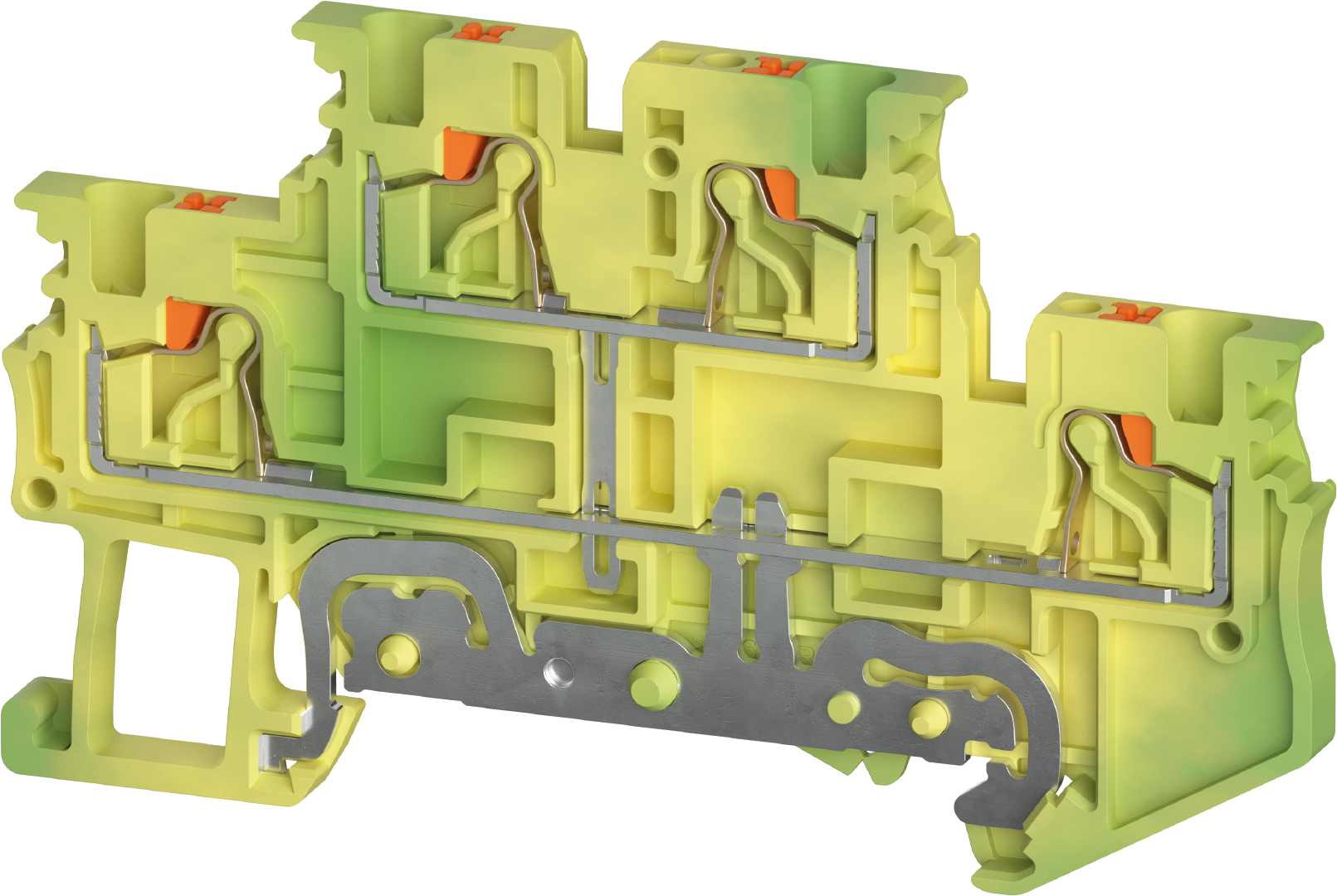

- 2-, 3-, or 4-pole (common) feed-through and protective earth terminal blocks

- 2- or 3-row, multi-tier terminal blocks

- Terminal blocks for fuses, knife disconnects, and current transformers

- Terminal blocks with special functions – sensor, motor, diode, pluggable, and more

- Supported conductors from 0.14 mm² to 25 mm² / 26 AWG to 4 AWG up to 82 amperes

- And a 3.5 mm wide terminal block with a nominal power of up to 300 V, 15 A, 14 AWG, IEC 500 V, 17.5 A, 0.14 to 1.5 mm², perfect for tight spaces

TECHNICAL DATA

| Parameter | Value |

|---|---|

| Conductor cross-sections | 1.5 mm² to 16 mm² |

| Rated current | up to 76 A (IEC) / 82 A (UL, CSA) |

| Rated voltage | up to 1000 V (IEC) / 600 V (UL, CSA) |

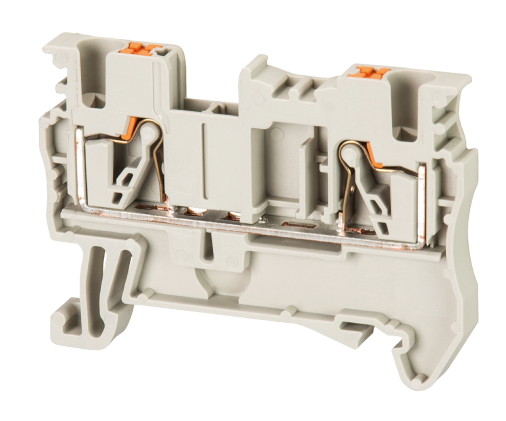

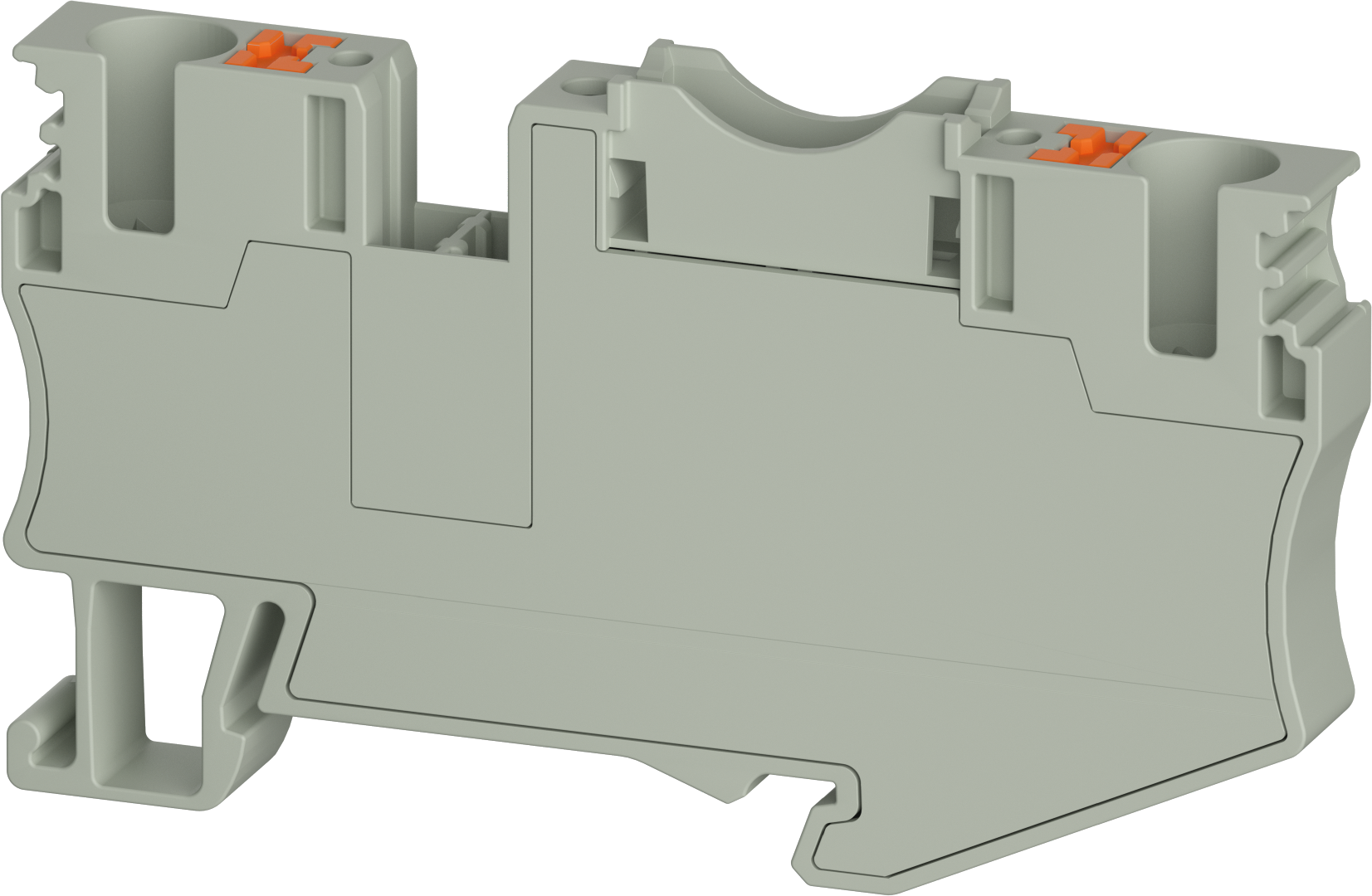

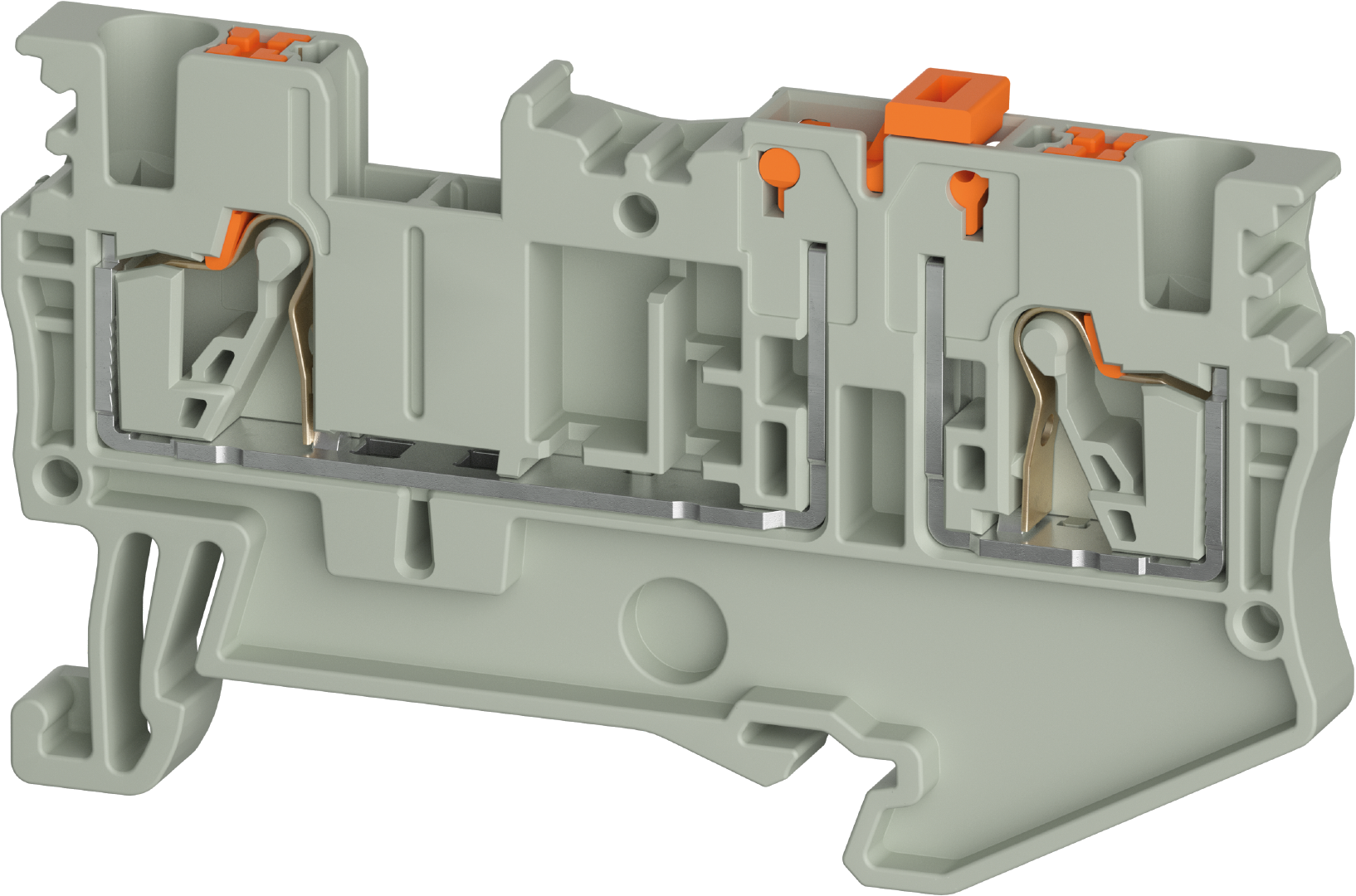

WTPN 2.5 mm² – Push-in terminal block

Compact 5.1 mm width, 24 A / 800 V, maintenance-free.

- nominal cross section: 2.5 mm²

- Rated current: 24 A

- Rated voltage: 800 V

- Width (Pitch): 5.1 mm

TECHNICAL DATA

Electrical data

- Rated current 24 A

- Rated voltage 800 V

- Impulse voltage 8 kV

- pollution degree 3

Connection & conductor range

- Connection: push-in terminal connection

- Solid: 0.14–4 mm²

- Fine-stranded: 0.14–2.5 mm²

- Stripping length 10 mm

Mechanics & design

- Levels: 1

- Terminals per level: 2

- width 5.1 mm

- Length 49 mm

- Height 35 mm

- Housing: PA, UL94 V0

- Mounting: DIN-rail 35 mm (top-hat)

Applications & standards

- Terminal blocks for electrical installations: yes

- End plate required: yes

- Insulating material: thermoplastic

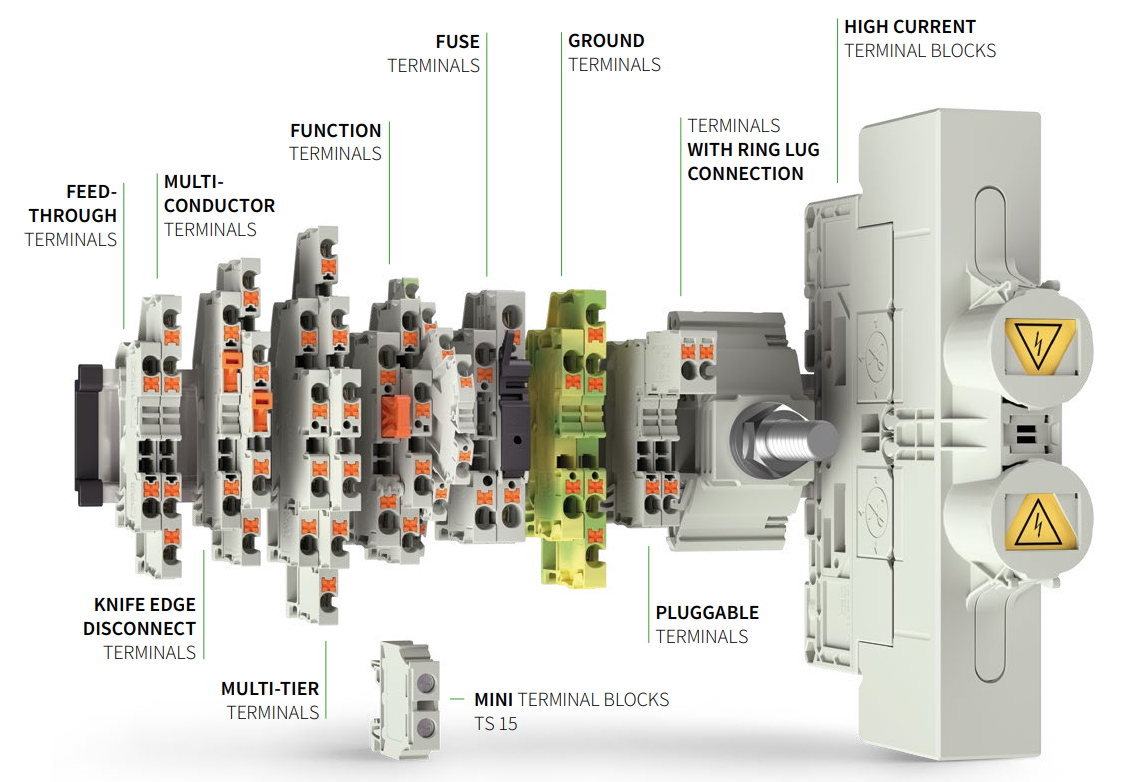

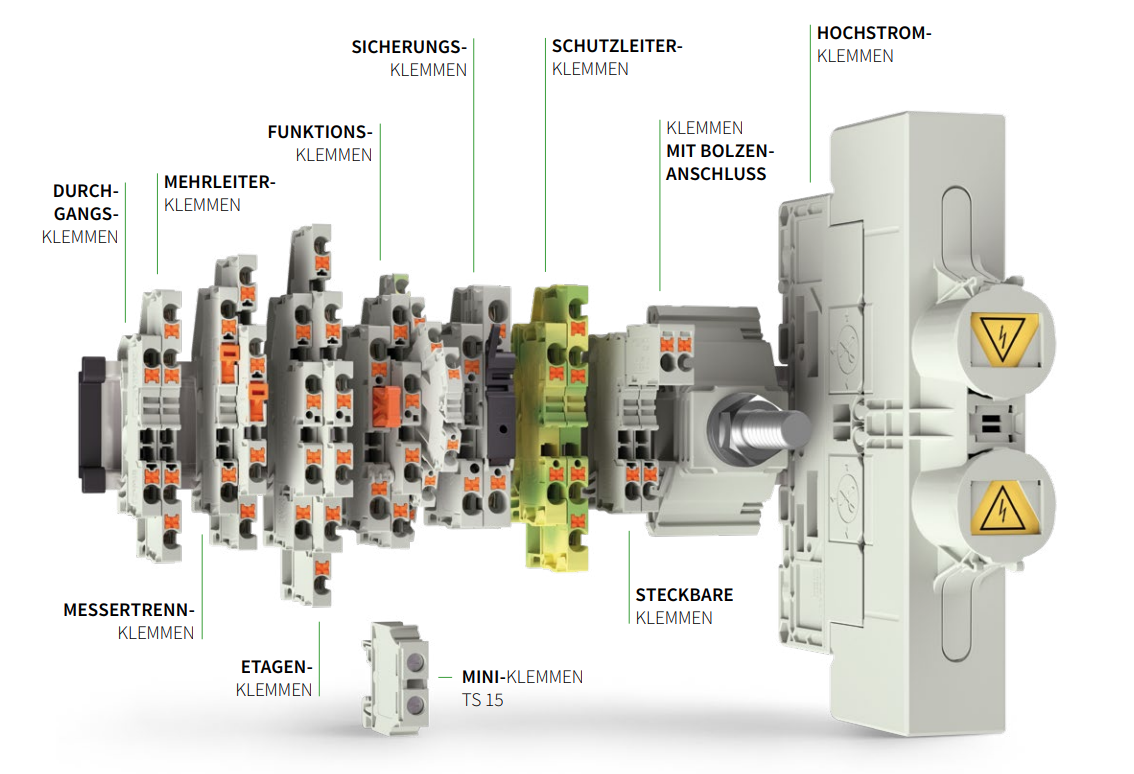

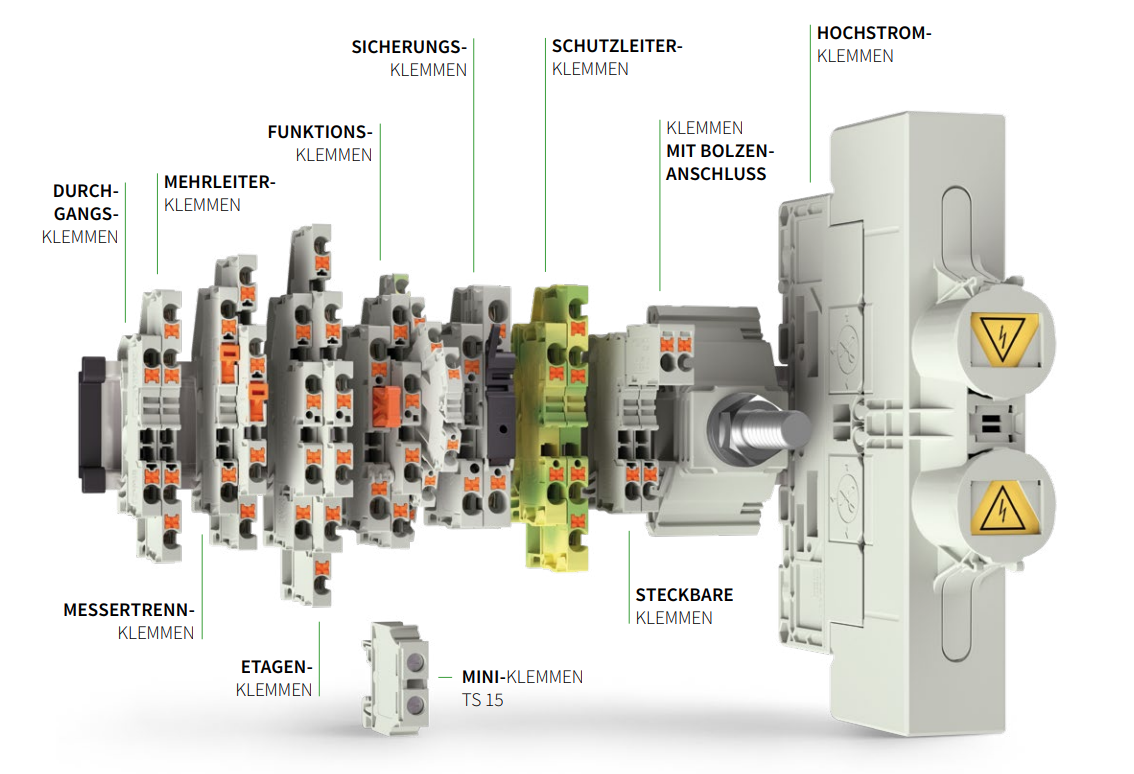

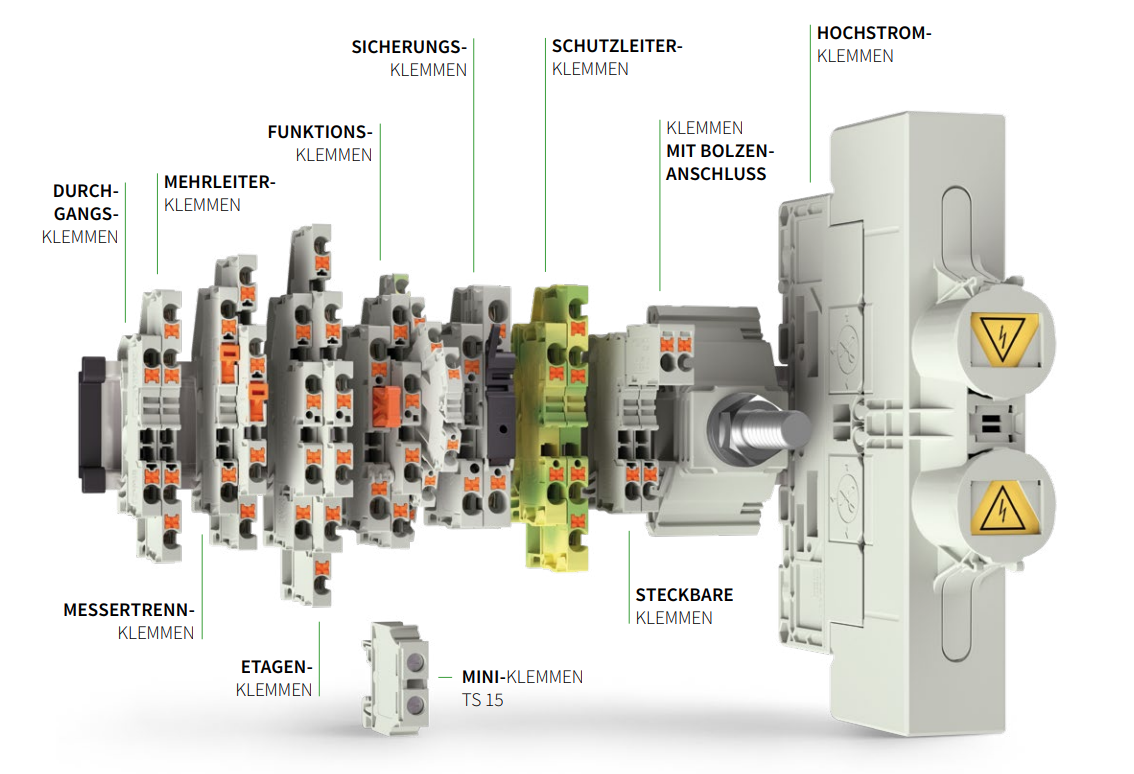

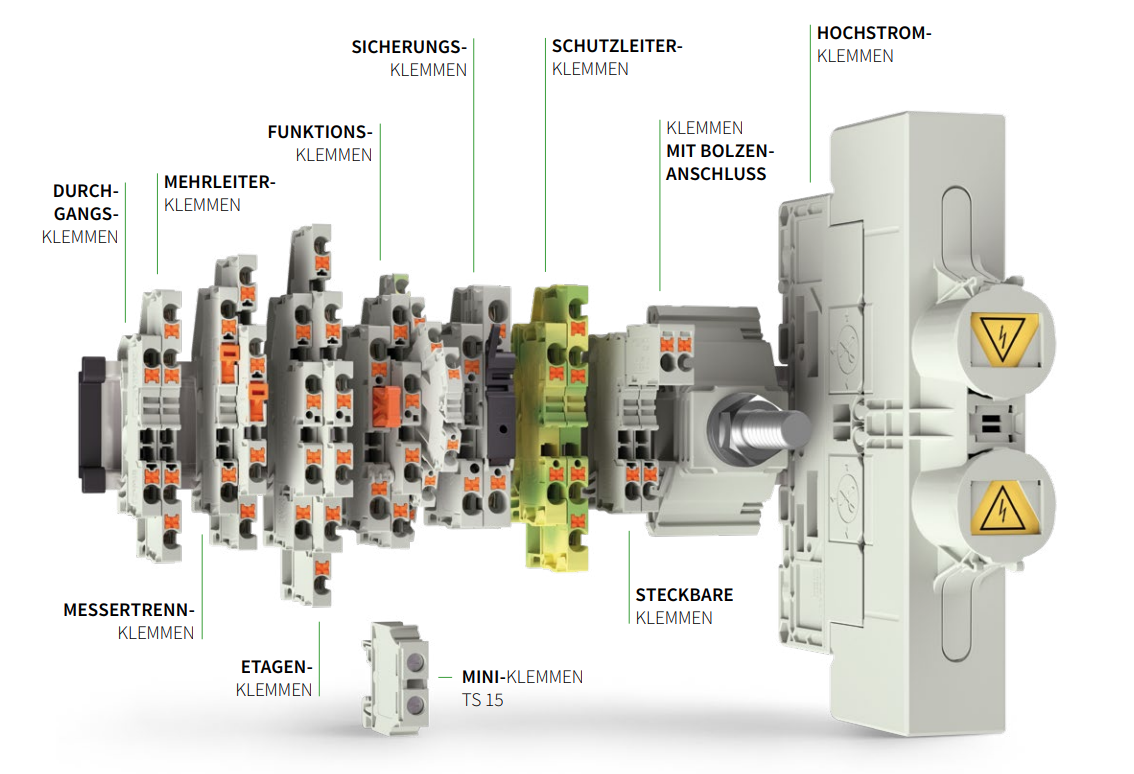

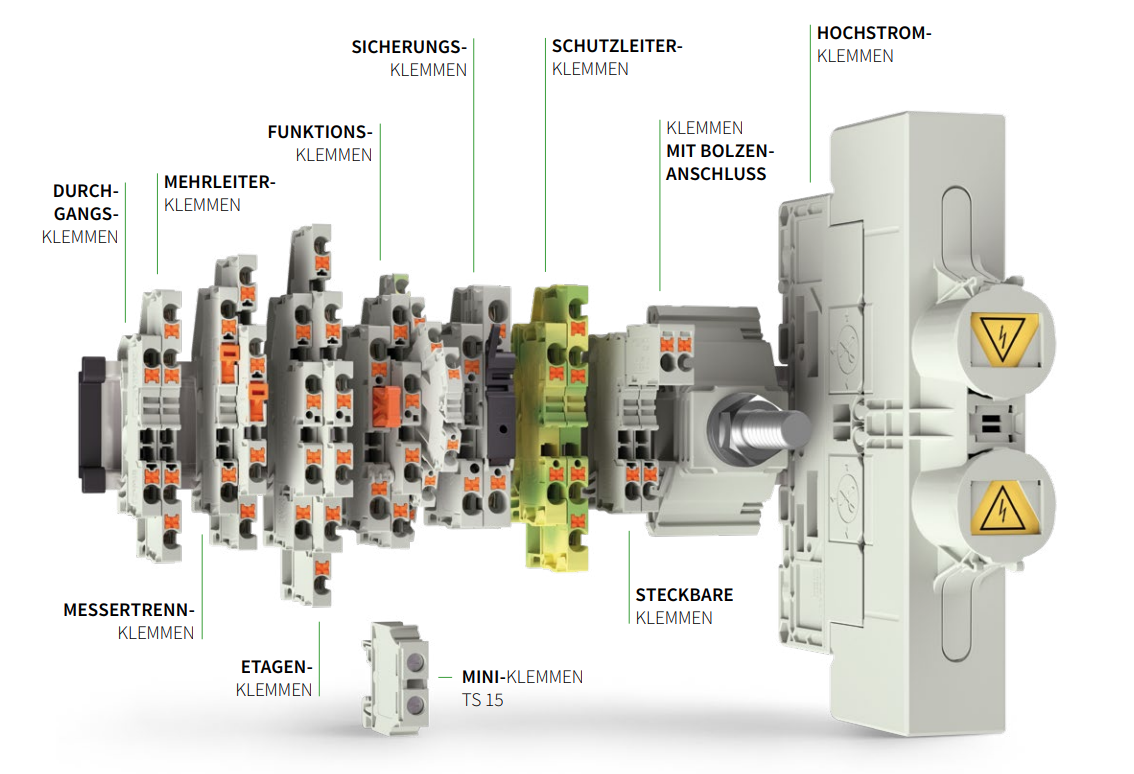

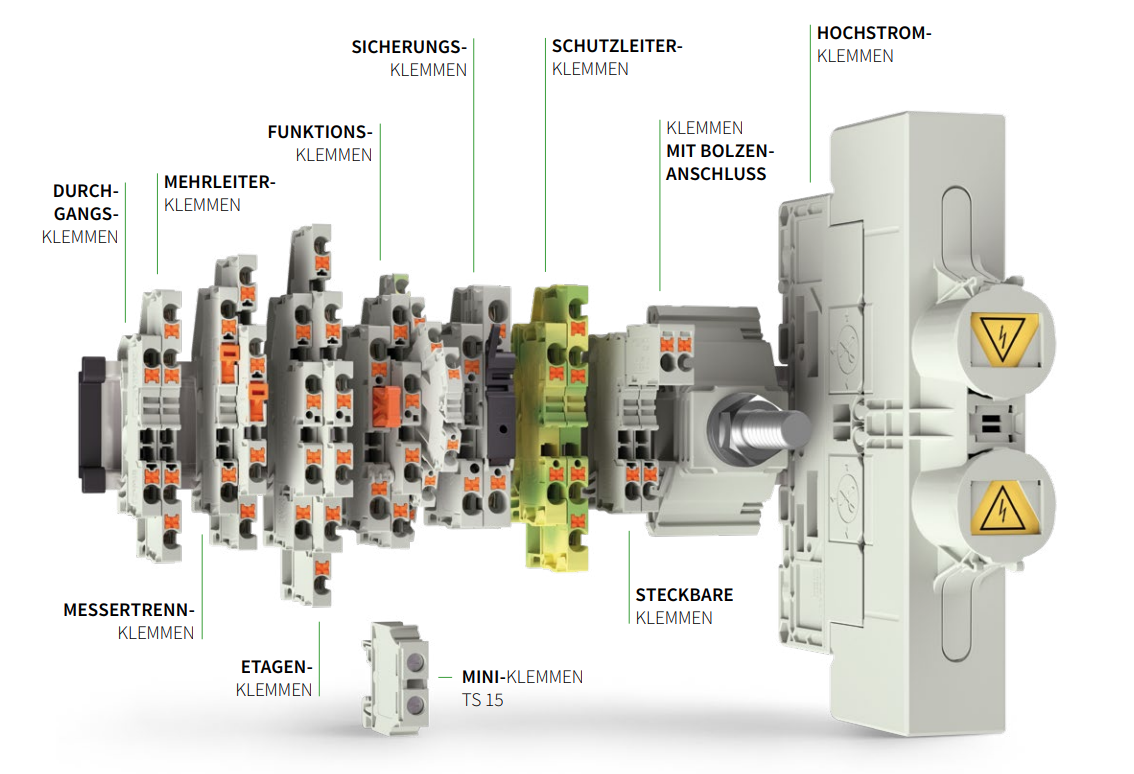

WTPN TERMINAL BLOCKS

– TECHNICAL RANGE AT A GLANCE

The WTPN range offers a wide selection of terminal blocks, complemented by a comprehensive range of accessories. This enables customized, space-saving wiring solutions for every application – from standard configurations to highly customized installations.

FEED-THROUGH TERMINAL BLOCKS

Reliable connection of conductors – in Push-in (WTPN) or screw version (WTN).

MULTI-CONDUCTOR TERMINAL BLOCKS

Efficient wiring of multiple conductors in one of the terminals – for flexible circuit configurations.

FUNCTION TERMINAL BLOCKS

For extended applications such as diode, resistor, or isolating functions.

FUSE TERMINAL BLOCKS

Simple protection of circuits with pluggable fuse inserts.

GROUND TERMINAL BLOCKS

Safe grounding – with automatic PE connection when snapping onto the mounting rail.

TERMINAL BLOCKS WITH RING LUG CONNECTION

For conductors with ring or fork cable lugs – robust connection technology for high currents.

HIGH-CURRENT TERMINAL BLOCKS

High-performance connections for cross-sections up to 240 mm² – ideal for power distribution.

KNIFE EDGE DISCONNECT TERMINAL BLOCKS

Ideal for testing, measuring, and maintenance work thanks to integrated disconnect knives.

MULTI-TIER TERMINAL BLOCKS

Compact multi-tier terminal blocks for maximum wiring density in the smallest space.

MINI TERMINAL BLOCKS (TS 15)

Perfect for confined spaces and small distributors – can be mounted on TS 15 mounting rail.

PLUGGABLE TERMINAL BLOCKS

Pluggable variants for modular applications and quick interchangeability.

WHY SHOULD YOU CHOOSE WTPN TERMINAL BLOCKS?

Fast, tool-free installation

WTPN terminal blocks enable quick and effortless wire insertion thanks to reliable push-in technology. Simply insert the conductor—no tool and no manual tightening of screws required. This saves time during wiring and increases the overall efficiency of the installation.

Vibration-resistant design

WTPN was designed for use in environments with constant movement and mechanical stress. The vibration-proof spring mechanism ensures stable connections – ideal for machine tools, mobile systems, as well as the automotive and rail industries.

High Contact Force

Thanks to a consistent spring mechanism, WTPN ensures a reliable electrical contact, regardless of the user's installation force. This reduces the risk of loose connections and prevents potential system failures.

Maintenance-free reliability

No retightening or additional checks required: WTPN terminal blocks maintain a constant clamping force throughout their entire life cycle. The Contact can be safely released with a screwdriver, ensuring safe and efficient maintenance.

Ideal for every wiring task in the control cabinet

From signal routing to power distribution, WTPN terminal blocks provide reliable, tool-free connections at all cabinet levels.

- Signal wiring – Secure, maintenance-free connections for system signals.

- Sensor/actuator wiring – Reliable integration of field devices in automation environments.

- Standard wiring – Universal solution for in-cabinet connections.

- Power distribution – Compact design enables efficient power distribution.

- Power feed-in – Tool-free connections reduce installation time.

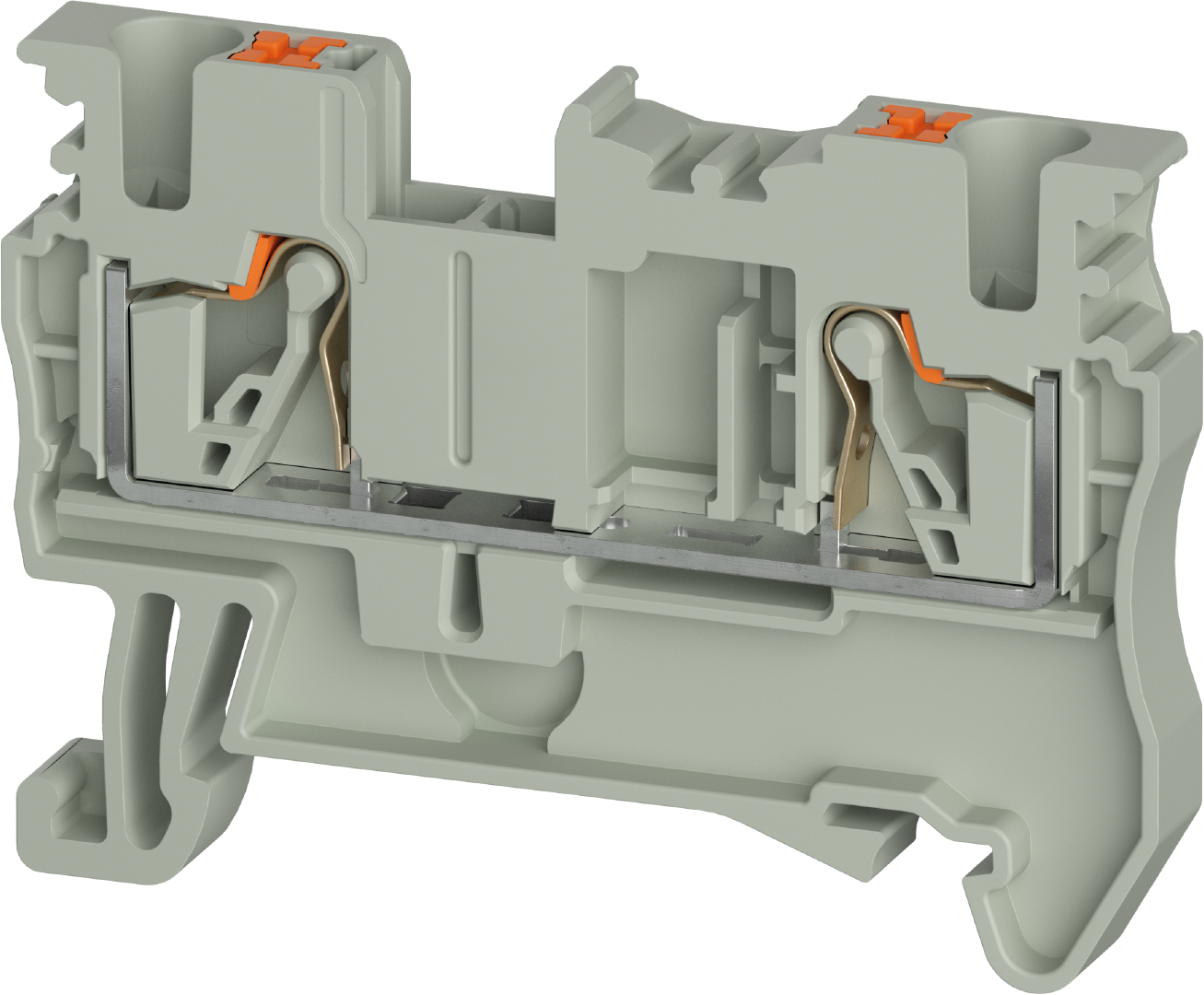

HOW THE SELOS WTPN PUSH-IN TERMINAL BLOCKS WORK

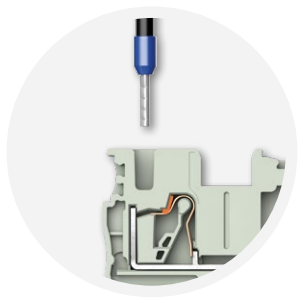

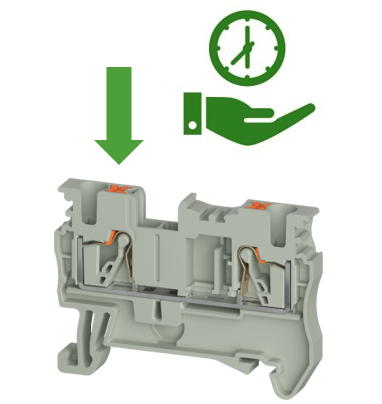

Step 1 - Insert until it stops

The conductor is simply inserted into the clamping point until it stops. Once in position, the spring holds it like a barbed hook, none damaging it.

Step 2 - Secure hold through spring tension

The spring is positioned so that it exerts no forces on the terminal housing. Regardless of whether a conductor is connected or not.

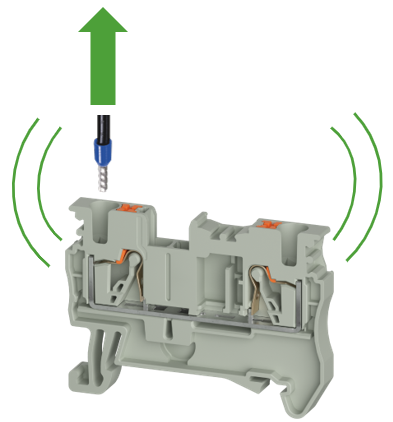

Step 3 - Tool-free release with the pusher

The conductor can likewise be released just as easily and with none damage. For this purpose, the so-called pusher is used – an instantly recognizable plastic element directly next to the conductor insertion opening.

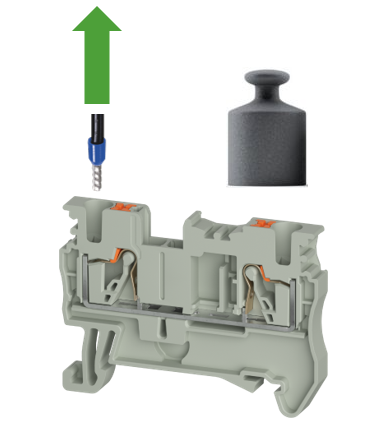

Step 4 - Release the conductor – simply with a screwdriver

The pusher closes concise with the terminal housing and can be pressed down with a standard screwdriver. This opens the spring and releases the conductor.

SMART CONNECTIVITY STARTS HERE

– THE FUTURE-PROOF ECOSYSTEM FOR TERMINAL BLOCKS

The WTPN series is part of our modernized, digitized ecosystem and offers:

SIMPLIFY YOUR PLANNING WITH SELOS PLAN

Our intuitive planning tool selos PLAN optimizes every step of your configuration and project planning. With a product-based user interface, it provides a clear, visual representation of your DIN rail assembly.

MARKING MADE EASY WITH SELOS PRINT

Clean, clear, and precise marking is essential for a well-organized control cabinet. With our powerful selos PRINT marking system, you can easily create marking labels for terminal block rows, tags, and cable markers for any application. Our new continuous marking system also makes the process more cost-effective.

COMPLETE YOUR SETUP WITH SMART ACCESSORIES

From partition plates to test plugs – our extensive accessory portfolio offers everything you need for the complete setup of your terminal strips. All components are designed for compatibility and ease of use, ensuring a tidy structure, reliable power, and simplified maintenance throughout the entire product life cycle.