samos® PRO

SAFETY CONTROLLER

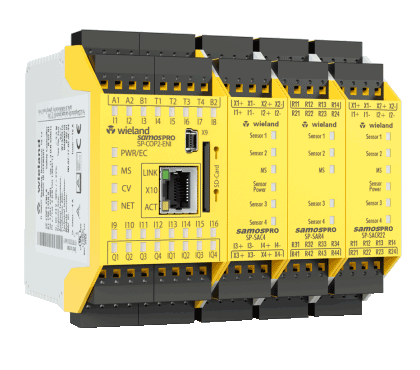

samos® PRO is the modular and programmable safety controller with intuitive software

SOFTWARE-PROGRAMMABLE SAFETY CONTROLLER

samos® PRO is the most compact, modular and programmable safety controller for machine and plant engineering. Safety functions are parameterised in compliance with standards using the intuitive and licence-free samos ® PLAN6 software. The focus is on user-friendly, standard-compliant implementation and simple integration into higher-level systems. The control system offers integrated Ethernet protocols and interfaces for this purpose.

Features OF THE SAFETY CONTROL SYSTEM

- Licence-free, intuitive samos® PLAN6 security software

- PROFINET IO, EtherNet/IP and Modbus TCP communication protocols integrated in the base module

- Compact base module with up to 20 inputs and outputs including terminals

- Optimum scalability thanks to a wide range of digital and analogue expansion models and gateways for all common industrial fieldbuses

- Operating temperature range from -25°C to +65°C

- Simple, intuitive and fast programming, verification and validation

- Cost-optimised thanks to customised, modular adaptation options

- Use at extreme temperatures

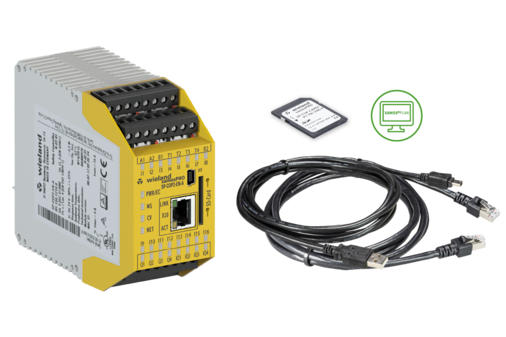

SAMOS® PRO COMPACT

STARTER-SET

The simple entry into the samos® safety world.

Test our safety system with our samos® PRO Starter-Set.

NOW ALSO WITH MOTION FUNCTION!

SAMOS® PRO MOTION

samos® PRO MOTION - All in one safety controller for motion monitoring

- Motion integrated in the base module for safe standstill, speed, direction and position monitoring

- Intuitive parameterisation with 6 TÜV-certified motion function blocks

- Simple monitoring of vertical and slow-moving axes with configurable speed and position windows

- High availability and safety despite vibrations

- Increased safety level through redundancy and shaft break detection

THE BASIC MODULES IN COMPARISON

SAFETY SOFTWARE SAMOS® PLAN6

samos® PLAN6 is the license-free, user-friendly software for standard-compliant programming of safety functions for samos® PRO safety controllers. samos® PLAN6 supports PLC programmers, electrical designers and developers.

All functions are designed for user-friendly operation:

- Easy hardware selection via automatic module configuration

- Application-specific, TÜV-certified libraries with over 65 function blocks

- Special libraries for analog value processing, muting and presses

- Fast verification and validation through oscilloscope function in off- and online mode

- Automatic, configurable documentation at the push of a button

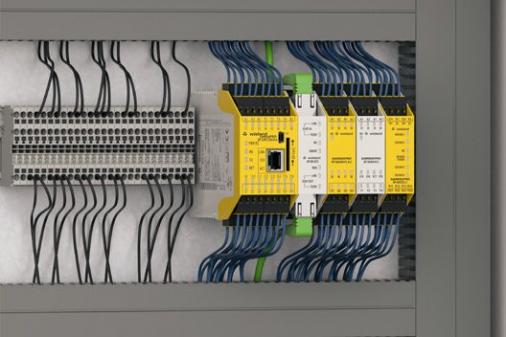

MODULAR SYSTEM DESIGN

FOR CUSTOMIZED SAFETY SOLUTIONS

Thanks to its modular system structure, samos® PRO implements safety functions efficiently and in a customized manner. With pluggable expansion modules, the safety controller is also suitable for large systems.

BASIC MODULE - COMPACT

- Integrated Industrial Ethernet protocols: PROFINET, EtherNet/IP, Modbus TCP

- Switching capacity of 4 A on each output pair

- Compact housing with 45 mm width

- 16 safe inputs, 4 safe outputs

- Use in extreme temperatures from -25°C to +65°C

- Flexible programming via mini-USB, Ethernet and removable SD memory card

- Connection via terminal blocks (screw or push-in terminal)

- On-site diagnostics via integrated LEDs and remote diagnostics via Ethernet interfaces

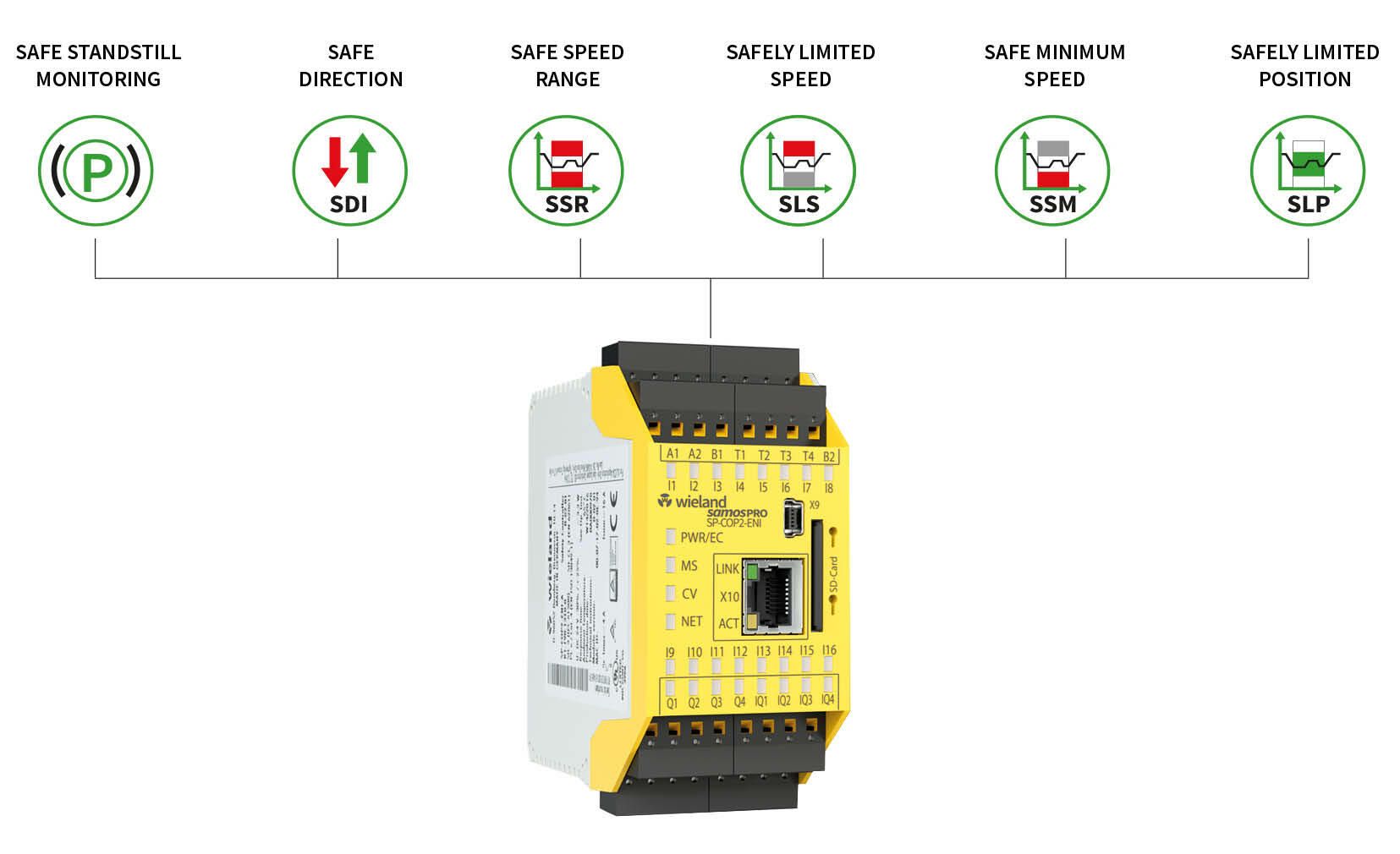

BASIC MODULE - MOTION

Samos® PRO MOTION combines the features of samos® PRO COMPACT with the functionalities of a motion safety controller.

- Motion safety functions integrated in accordance with EN 61800-5-2:

- Safe standstill monitoring

- Safely reduced speed (SLS)

- Safe speed range (SSR)

- Safe speed monitoring (SMS)

- Safe direction of rotation (SDI)

- Safe position monitoring (SLP)

- 4 fast and safe motion inputs with 70kHz

Digital modules

- Expandable with up to 12 digital I/O modules

- Up to 116 safe inputs

- Up to 56 Safe Outputs

Analog modules

- Monitoring of force, temperature, pressure, flow, distance, inclination and flow rates

- Up to 48 analog sensors can be connected in 2/3/4-wire technology

- Easy programming of limits, ranges, ratios and differences with application-specific, TÜV-certified function blocks

GATEWAY MODULES

- Support of CANopen, PROFIBUS and EtherCAT via external gateways

- Parallel use of up to 2 external and one internal gateway

- Possibility of remote diagnosis

TO THE EXTERNAL GATEWAYS

SAFE RELAY FOR DRIVE MONITORING

- Sensor-less standstill monitoring

- Standstill monitoring via HTL encoder or initiators

- PL e / SIL 3

- Pluggable terminals with screw or push-in connection

- Up to 8 A switching power

Certified safety

samos®PRO COMPACT is also certified for your safety application.

- IEC 60204-1/IEC 62061/EN 13849-1: Safety of machinery

- EN 692: Mechanical presses

- EN 693: Hydraulic presses

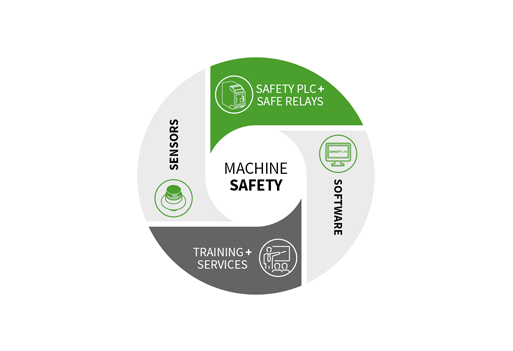

FUNCTIONAL SAFETY

PRACTICAL HANDBOOK

With the Functional Safety Practical Handbook, we offer you user-oriented assistance in designing safety solutions. Experienced practitioners and standards experts provide a comprehensive insight into the most important topics relating to functional safety. Application examples and sample solutions help to put theoretical knowledge into practice.

DOWNLOADS

CAREFREE TO CE MARKING -

WITH THE WIELAND SAFETY EXPERTS

Safety has been our daily business – for more than 30 years. On the way to CE marking and safe operation, we are your reliable partner and contribute our experience to your project. Whether training or consulting: We put together your individual all-round carefree package for thestandard-compliant implementation of your machines. We support manufacturers and operators either in specific sub-steps such as inspection and overrun measurement, risk assessment of machines or validation of safety functions according to EN ISO 13849-2, or we accompany them holistically through the CE process up to CE conformity assessment according to machine directives.