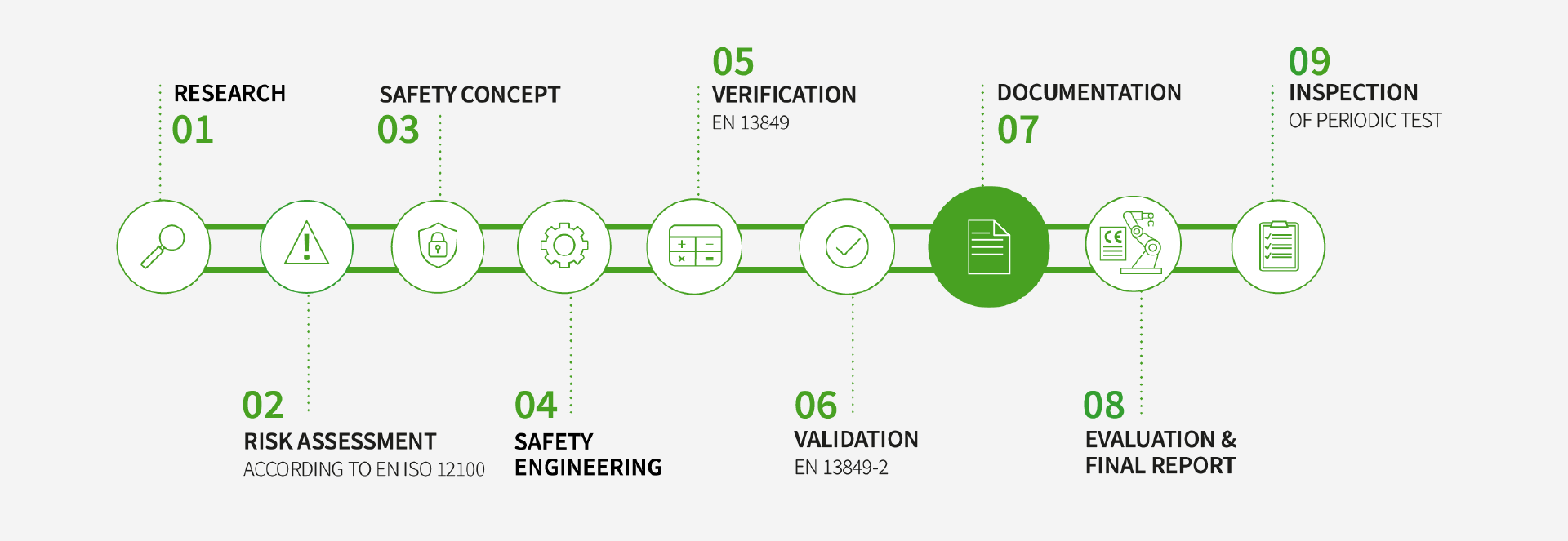

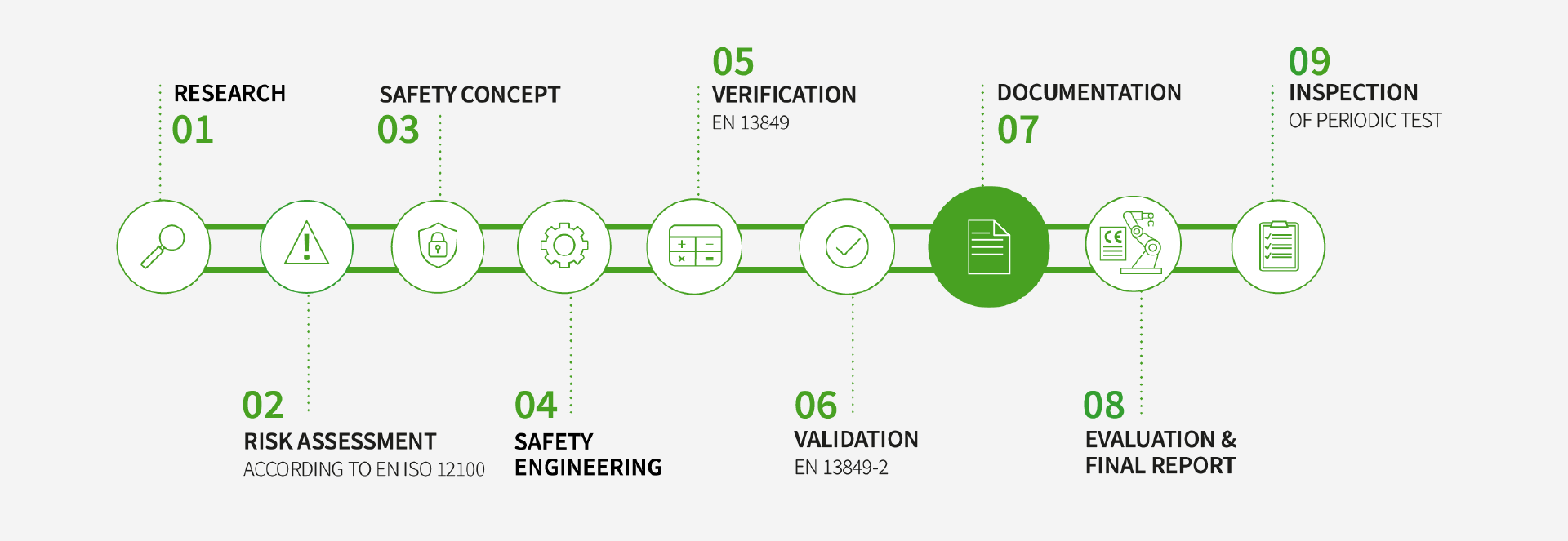

• 01 Research • 02 Risk Assessment • 03 Safety Concept • 04 Safety Engineering • 05 Verification

• 06 Validation ▸ 07 Documentation • 08 Evaluation & Final Report • 09 Inspection

07 DOCUMENTATION –

THE FOUNDATION FOR

LEGAL COMPLIANCE

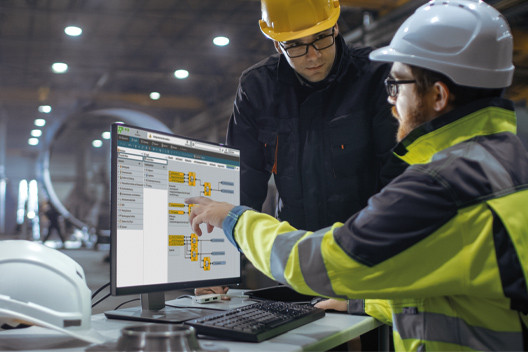

Documentation is one of the most critical steps in the CE process and forms the basis for the Declaration of Conformity. In this phase, all relevant documents—such as risk assessments, validation reports, and technical specifications—are compiled, reviewed, and finalized. The goal is to create complete and consistent documentation that fully complies with all applicable standards and directives.

With Wieland as your partner, you can ensure that your documentation meets the highest legal and normative standards—leaving no gaps.

Objective:

To prepare and review complete documentation packages as the foundation for the EU Declaration of Conformity for each machine.

Description:

Documentation is a crucial component of the CE process. It includes all necessary records, such as the risk assessment, safety concept, test protocols, and validation results. Once compiled, the completeness of these documents is checked to ensure that all requirements are met. Opportunities for improvement are identified to raise the quality of the documentation.

- CE Coordinators: Responsible for compiling and verifying all documentation.

- Quality Managers: Ensure compliance with normative requirements and provide proper evidence.

- Safety Engineers: Deliver the technical documents needed for the CE Declaration of Conformity.

Target Audience:

⚙️ CHALLENGES & COMMON ISSUES

- Incomplete or inconsistent documentation:

A systematic approach is often lacking, resulting in inconsistent or missing documents such as risk assessments, validation reports, or specifications.

- Misapplication of standards and directives:

Correctly applying and documenting the relevant standards and directives requires in-depth regulatory knowledge. Misinterpretations or missing evidence can pose legal risks.

- Lack of in-house expertise:

Teams are often not sufficiently trained to correctly interpret and apply legal and normative requirements such as the Machinery Directive or CE conformity. This leads to delays or errors in the process.

🔧 HOW WE SUPPORT YOU

- Documentation review:

Our experts audit your documentation to ensure completeness and compliance with relevant standards and directives.

- Optimization:

We provide actionable advice to help you streamline and standardize your documentation process.

- Training and workshops:

Take advantage of our seminars covering topics like the Machinery Directive, CE compliance, liability issues, or retrofitting of existing machinery.

Need support with this step?

Our experts are always here to support you with practical assistance

Contact usCONSULTING SERVICES

Expertise on demand – for a safe and compliant future.

Services | Audience | Description | |

|---|---|---|---|

| CE documentation according to the machinery directive | Manufacturers and Operators | We create the required CE documentation for you to prove compliance with legal requirements. | Learn more |

| Machine safety consultation day on-site | Manufacturers and Operators | Our experts visit your site and provide advice on optimizing the safety of your machines and facilities to ensure safe and reliable production. | Learn more |

| Checking the operating instructions for CE conformity | Manufacturers and Operators | We check the operating instructions of your machines for CE conformity and ensure that they contain all required safety information. | Learn more |

| CE conformity assessment according to machinery directives | Operators | Our check of the CE conformity of your machines provides the certainty that they meet requirements and your production is legally secure. | Learn more |

| Effects of substantial modifications to machinery for CE marking | Operators | We regularly check your machines for significant changes to ensure that they continue to meet applicable safety standards and do not affect your operational processes. | Learn More |

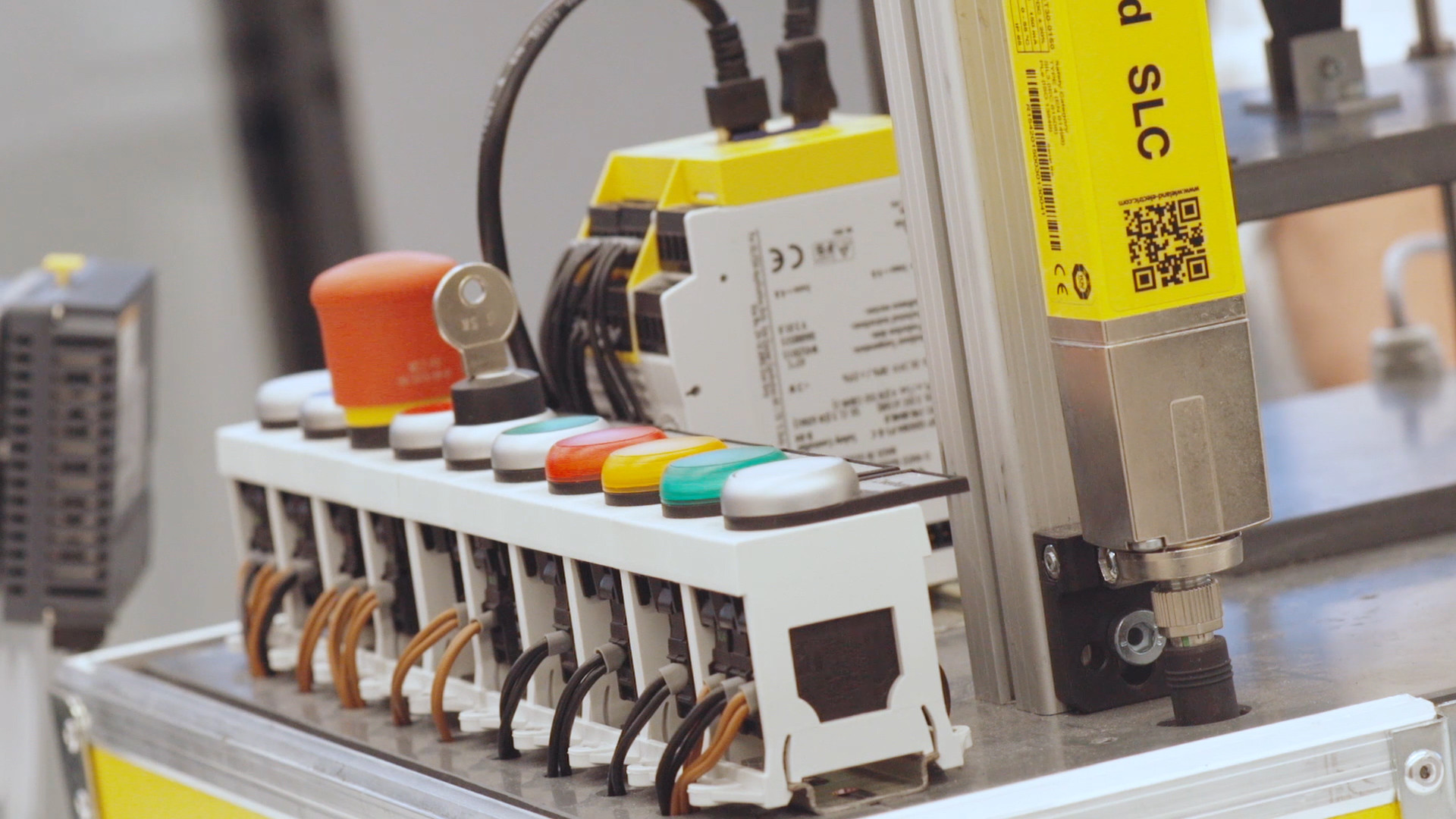

| Verification of safety functions according to DIN EN ISO 13849-1 | Manufacturers and Operators | Our verification of your safety concept according to EN ISO 13849-1 ensures that your safety measures meet applicable requirements and your production is safe. | Learn more |

| Validation of the safety functions according to EN ISO 13849-2 | Manufacturers and Operators | Our validation of the safety functions of your machines according to EN ISO 13849-2 ensures that the technical safety measures defined in your safety concept are tested for effectiveness. | Learn more |

| Testing of safety devices and equipment on machinery | Operators | Our inspection of the safety devices on your machines ensures their functionality and compliance with legal requirements. | Learn more |

Consulting that creates safety – Discover our full range!

View all consulting servicesTRAININGS

Strengthen your independence and build long-term expertise.

Course | Description | Certification | |

| Certified Electrical Safety Engineer | The 3-day course focuses on the electrical section, providing you with a complete overview of the CE process with a final examination for TÜV certification. | ✅ TÜV-certified | Learn more |

| Refresher Seminar – Certified Safety Engineer | Our course offers you the opportunity to renew your certification and be well-prepared for the future. | ✅ TÜV-certified | Learn more |

| Certified Functional Safety Expert (CFSE) for Electrical and Fluid Power Systems | Comprehensive training for electrical & fluid safety systems. | ✅ International certification | Learn more |

| Validation of safety application software in machinery | This course covers the validation of safety software in mechanical engineering, including challenges in the application of safety controls. | ✅ Wieland Training certificate | Learn more |

| Fundamentals of functional safety | The course provides legal and normative foundations for assessing the functional safety of a machine. | ✅ Wieland Training certificate | Learn more |

| Design and validation of safety functions Sistema | In this course, you will learn how to model and evaluate the safety of your own machine according to EN ISO 13849-1 using SISTEMA. | ✅ Wieland Training certificate | Learn more |

| Calculation of complex safety functions according to EN ISO 13849-1 | The seminar deals with procedures for modeling and calculating safety functions according to EN ISO 13849-1, which deviate from the structures shown in the standard. | ✅ Wieland Training certificate | Learn more |

Training for your expertise – deepen your knowledge now!

View all training coursesDOWNLOADS

PRACTICAL MANUAL

FOR FUNCTIONAL SAFETY

Experience knowledge at your fingertips. Our functional safety practical handbook offers simple guidance and easy-to-understand examples for designing safety solutions. Experienced practitioners and standards experts provide a comprehensive insight into the most important topics relating to functional safety. Application examples of safety circuits and Sistema calculations help maintain the longevity of your machine’s operating lifecycle.

YOUR ORIENTATION

IN THE CE PROCESS

You are currently at Step 07: Documentation.

In this step, the results of all preceding phases are compiled and reviewed to establish a solid foundation for a legally compliant CE Declaration of Conformity.

To keep an overview of the entire CE process, you’ll find the summary here:

01 Research

Identify all applicable standards, directives, and legal requirements for your machine type – the foundation for a legally secure and smooth CE process.

02 Risk Assessment

Evaluate all potential hazards throughout the machine’s lifecycle according to EN ISO 12100 and lay the groundwork for a sound safety concept.

04 Safety Engineering

Bring your safety concept to life with well-designed technology and develop standards-compliant safety software – for a safe and productive machine.

03 Safety Concept

Derive specific protective measures based on the risk assessment – compliant with EN ISO 13849-1 and tailored to your operational needs.

05 Verification

Verify the implementation of protective measures in line with EN ISO 13849-1 – especially with regard to the required performance level.

07 Documentation

Ensure that all records – from risk assessment to validation – are complete, consistent, and CE-compliant.

09 Inspection

Conduct regular inspections to ensure the functionality of your safety measures throughout the machine’s entire lifecycle.

06 Validation

Test directly on the machine whether all technical safety measures function reliably and meet the specified requirements.

08 Evaluation & Final Report

Compile and confirm all relevant evidence in a final report – forming the basis for the Declaration of Conformity.