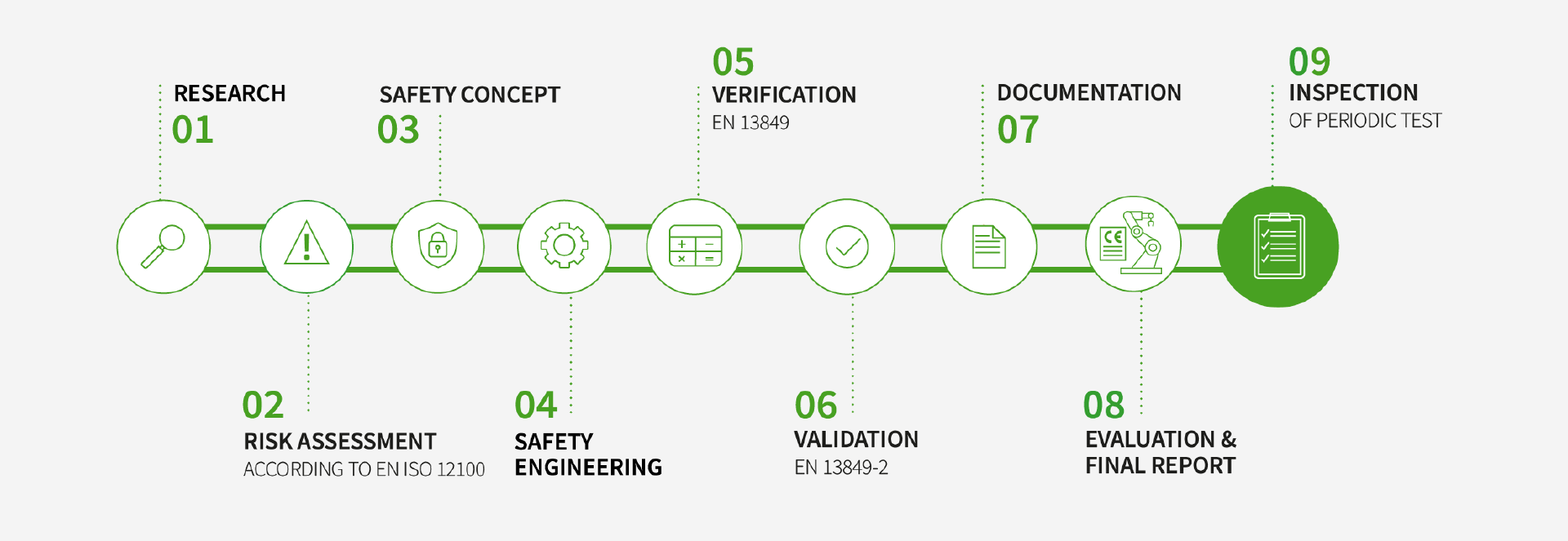

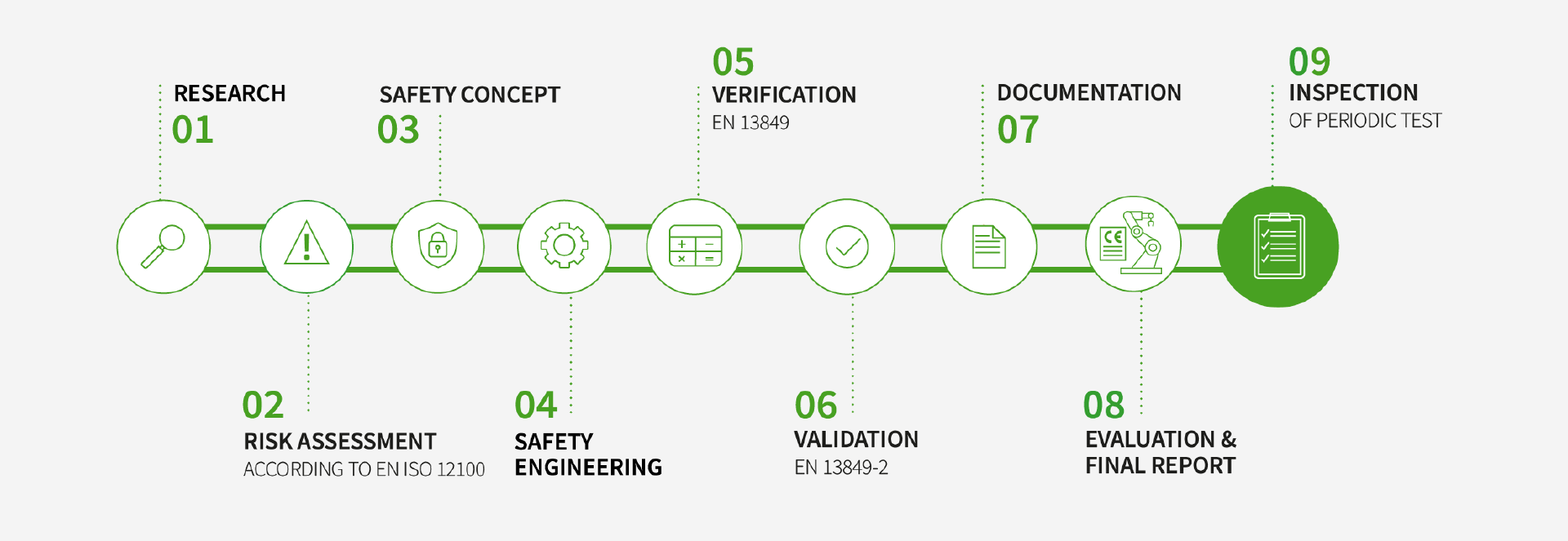

• 01 Research • 02 Risk Assessment • 03 Safety Concept • 04 Safety Engineering • 05 Verification

• 06 Validation • 07 Documentation • 08 Evaluation & Final Report ▸ 09 Inspection

09 INSPECTION –

ENSURING LASTING SAFETY

Inspection is the final step in the CE process. It ensures that all protective measures function properly not just at the time of commissioning but continue to do so throughout the machine’s entire lifecycle. Thorough inspections – including repeat measurements of stopping distances and checks of protective systems – are essential to maintaining operational safety and compliance with applicable standards.

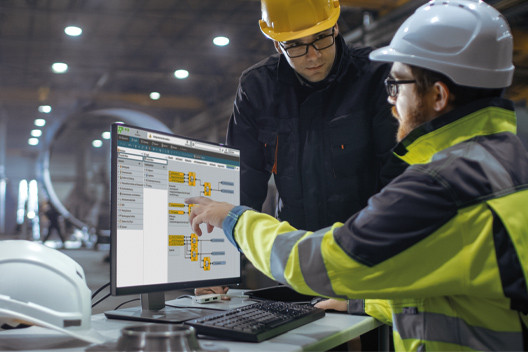

With Wieland, you benefit from a systematic approach and hands-on training that prepares your teams for recurring inspections – including retrofit projects.

Objective:

Regular inspection of technical protective measures to ensure machine safety throughout its operational lifecycle.

Description:

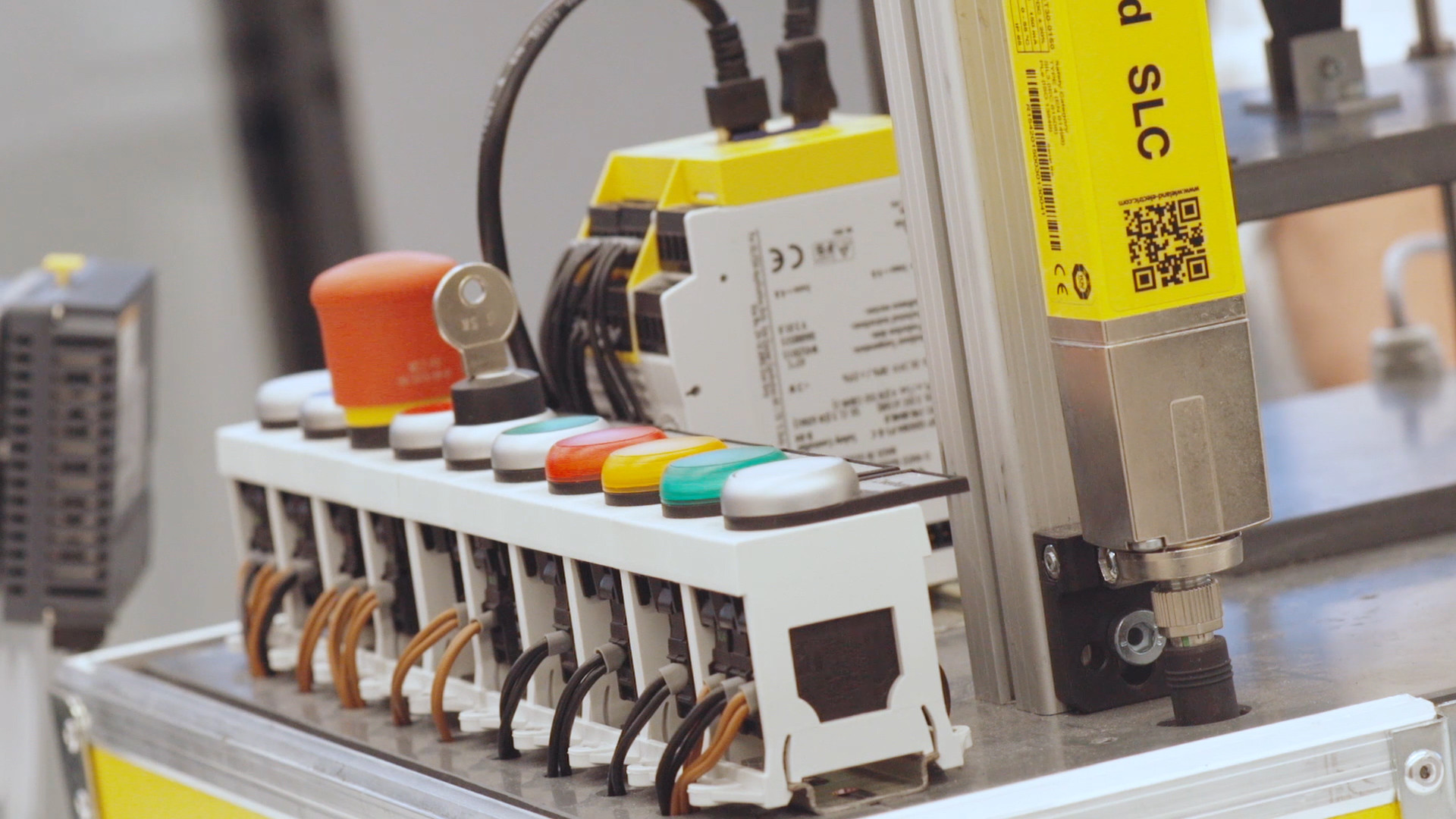

The first inspection takes place during commissioning to verify that all protective measures are correctly installed and functioning. During operation, regular inspections – such as stopping distance measurements – are conducted to ensure ongoing compliance with safety requirements and to detect any wear or performance issues.

- Maintenance Technicians: Responsible for ongoing functional checks.

- Safety Officers: Ensure compliance with safety regulations during operation.

- CE Coordinators: Integrate inspection findings into the ongoing conformity assessment process.

Target Audience:

⚙️ CHALLENGES & COMMON ISSUES

- Inadequate inspection during commissioning:

Protective measures are often insufficiently checked during startup, potentially leading to safety gaps and liability risks.

- Lack of regular in-use inspections:

Many companies do not perform recurring stopping distance measurements or system checks, which can result in long-term malfunctions and safety hazards.

- Limited expertise in recurring inspections:

Especially with retrofit projects, companies often lack clear procedures or trained personnel familiar with inspection requirements and applicable standards.

🔧 HOW WE SUPPORT YOU

- Inspection services:

Our experts perform protective system checks during commissioning and operational phases, including stopping time measurements.

- Training:

We offer seminars on topics like retrofit projects to provide in-depth training for your staff.

- Ongoing support:

We assist you in planning and executing regular inspections to maintain long-term machine safety.

Need support with this step?

Our experts are always here to support you with practical assistance

Contact usCONSULTING SERVICES

Expertise on demand – for a safe and compliant future.

Services | Audience | Description | |

|---|---|---|---|

| Machine safety consultation day on-site | Manufacturers and Operators | Our experts visit your site and provide advice on optimizing the safety of your machines and facilities to ensure safe and reliable production. | Learn more |

| Checking the operating instructions for CE conformity | Manufacturers and Operators | We check the operating instructions of your machines for CE conformity and ensure that they contain all required safety information. | Learn more |

| Effects of substantial modifications to machinery for CE marking | Operators | We regularly check your machines for significant changes to ensure that they continue to meet applicable safety standards and do not affect your operational processes. | Learn More |

| Hazard and risk analysis of machinery for operators | Operators | Durch unsere umfassende Gefährdungsbeurteilung erhalten Sie wertvolle Empfehlungen zur Verbesserung der Sicherheit Ihrer Maschinen und reduzieren das Risiko von Unfällen. | Learn more |

| Testing of safety devices and equipment on machinery | Operators | Our inspection of the safety devices on your machines ensures their functionality and compliance with legal requirements. | Learn more |

| Check the safety-related commissioning of machines | Manufacturers and Operators | We inspect your machines for technical safety suitability before commissioning and ensure that they meet applicable safety standards and ensure safe operation. | Learn more |

| Machine safety inspection and overrun measurement | Operators | Regular inspections and follow-up measurements ensure that your machines can continue to be operated safely and reliably. | Learn more |

Consulting that creates safety – Discover our full range!

View all consulting servicesTRAININGS

Strengthen your independence and build long-term expertise.

Course | Description | Certification | |

| Certified Electrical Safety Engineer | The 3-day course focuses on the electrical section, providing you with a complete overview of the CE process with a final examination for TÜV certification. | ✅ TÜV-certified | Learn more |

| Refresher Seminar – Certified Safety Engineer | Our course offers you the opportunity to renew your certification and be well-prepared for the future. | ✅ TÜV-certified | Learn more |

| Certified Functional Safety Expert (CFSE) for Electrical and Fluid Power Systems | Comprehensive training for electrical & fluid safety systems. | ✅ International certification | Learn more |

| Machinery directive, CE declaration and legal liability | This seminar covers formal questions concerning machine safety from a management perspective. | ✅ Wieland Training certificate | Learn more |

| Fundamentals of functional safety | The course provides legal and normative foundations for assessing the functional safety of a machine. | ✅ Wieland Training certificate | Learn more |

| Retrofit of used machinery and the significant modification | In this course, you will learn how to carry out the conversion of old machines in the existing machine park. | ✅ Wieland Training certificate | Learn more |

| Inspection of optical protection devices (ESPE) | The seminar familiarizes participants with the legal and normative foundations for the design and inspection of optoelectronic protective devices or non-contact protective devices (NCD). | ✅ Wieland Training certificate | Learn more |

Training for your expertise – deepen your knowledge now!

View all training coursesDOWNLOADS

PRACTICAL MANUAL

FOR FUNCTIONAL SAFETY

Experience knowledge at your fingertips. Our functional safety practical handbook offers simple guidance and easy-to-understand examples for designing safety solutions. Experienced practitioners and standards experts provide a comprehensive insight into the most important topics relating to functional safety. Application examples of safety circuits and Sistema calculations help maintain the longevity of your machine’s operating lifecycle.

YOUR ORIENTATION

IN THE CE PROCESS

You are currently at Step 09: Inspection.

This step is essential to ensure that the implemented safety measures function properly throughout the entire lifecycle of the machine. Regular inspections are not only crucial for safety, but also a key component in meeting legal requirements.

To keep an overview of the entire CE process, you’ll find the summary here:

01 Research

Identify all applicable standards, directives, and legal requirements for your machine type – the foundation for a legally secure and smooth CE process.

02 Risk Assessment

Evaluate all potential hazards throughout the machine’s lifecycle according to EN ISO 12100 and lay the groundwork for a sound safety concept.

04 Safety Engineering

Bring your safety concept to life with well-designed technology and develop standards-compliant safety software – for a safe and productive machine.

03 Safety Concept

Derive specific protective measures based on the risk assessment – compliant with EN ISO 13849-1 and tailored to your operational needs.

05 Verification

Verify the implementation of protective measures in line with EN ISO 13849-1 – especially with regard to the required performance level.

07 Documentation

Ensure that all records – from risk assessment to validation – are complete, consistent, and CE-compliant.

09 Inspection

Conduct regular inspections to ensure the functionality of your safety measures throughout the machine’s entire lifecycle.

06 Validation

Test directly on the machine whether all technical safety measures function reliably and meet the specified requirements.

08 Evaluation & Final Report

Compile and confirm all relevant evidence in a final report – forming the basis for the Declaration of Conformity.