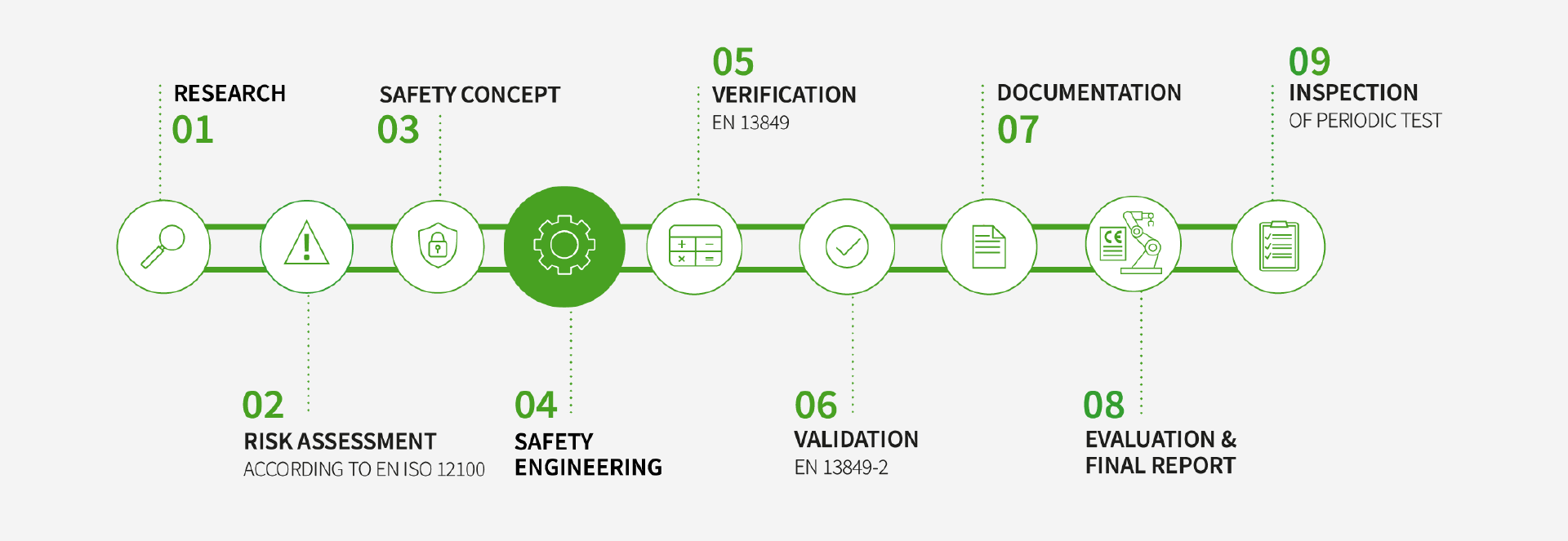

• 01 Research • 02 Risk Assessment • 03 Safety Concept ▸ 04 Safety Engineering • 05 Verification

• 06 Validation • 07 Documentation • 08 Evaluation & Final Report • 09 Inspection

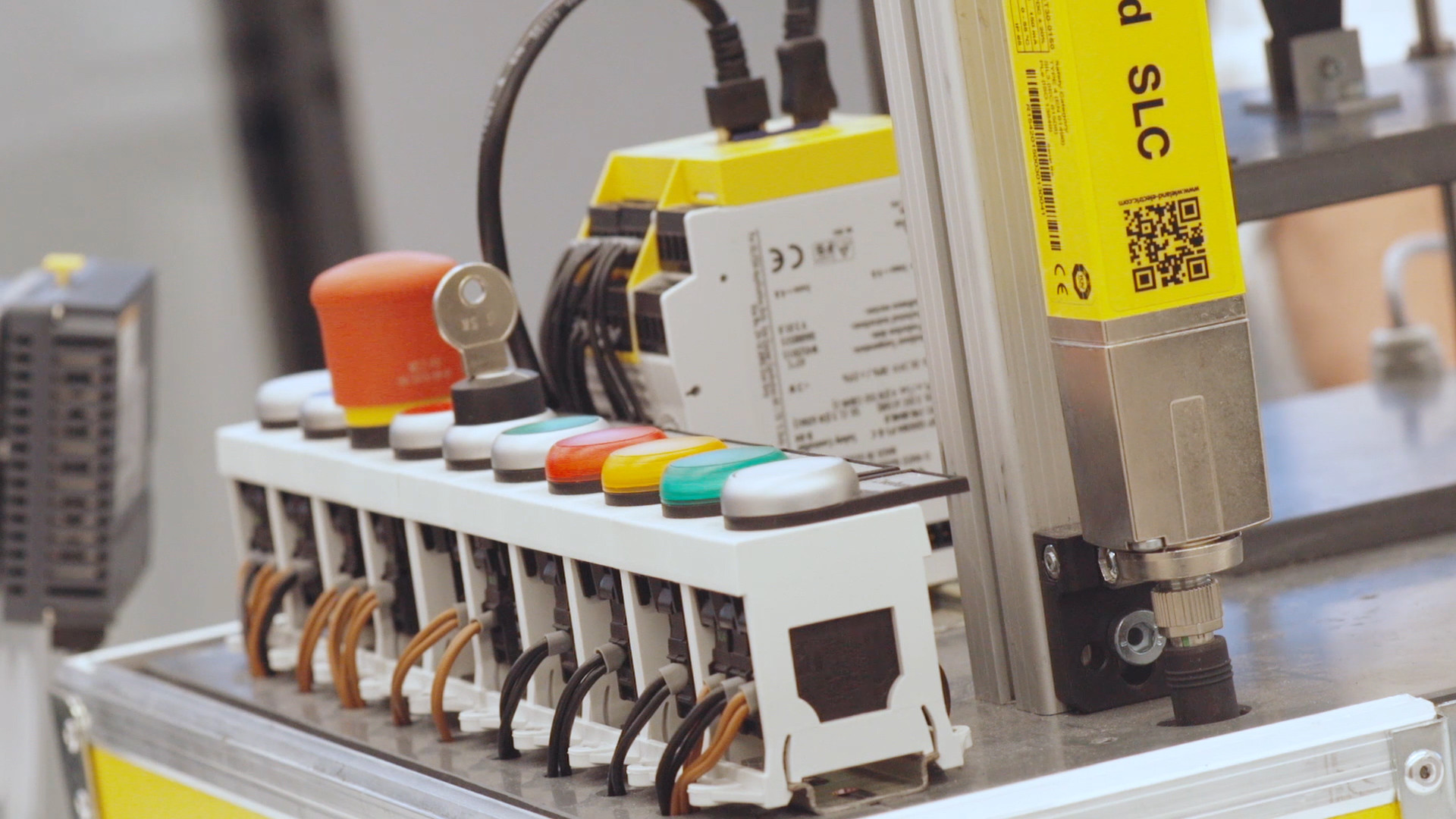

04 SAFETY ENGINEERING – FROM CONCEPT TO IMPLEMENTATION

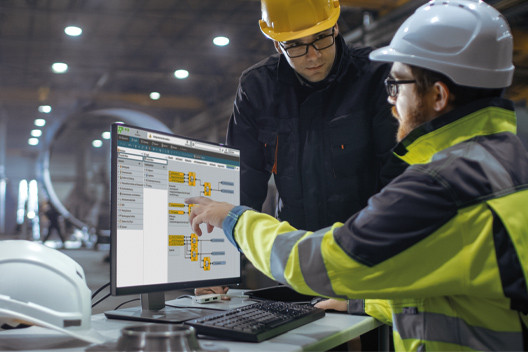

Safety Engineering is the next logical step in the CE process, where previously developed safety concepts are translated into concrete measures. In this phase, appropriate protective measures are selected and safety-related software solutions are developed to meet the defined requirements.

With Wieland, you benefit from practical support – from selecting the right components to software development, for example with samos® PLAN 6. This ensures that your safety solutions are implemented efficiently and in compliance with applicable standards.