SAMOS® PLAN6

– License-free software for programming safety controllers

Direct download – no detours

DEVELOP EFFICIENTLY.

VALIDATE SAFELY.

DOCUMENT IN COMPLIANCE.

Whether you are a safety engineer, electrical designer, or HSE manager – samos® PLAN6 supports you exactly where it matters most: in the standards-compliant design and documentation of safety-related control systems.

The functional safety software combines intuitive operation, automatic hardware detection, and diagnostics into an end-to-end safety solution.

Whether inputs and outputs, safety function blocks, or motion functions all components interconnect seamlessly to form a complete safety system that is fully license-free and ready to use right away.

This enables you to implement safety functions faster, minimize sources of error, and ensure standards-compliant execution.

The Problem

The standards compliant programming of safety functions is extensive and complex. Safety engineers, electrical designers, and developers must plan safety functions carefully, document them thoroughly, and implement them in line with applicable standards, often while working under time pressure, managing multiple interfaces, and facing increasing levels of risk.

Our Solution

samos® PLAN6 makes safety engineering simple.

The intuitive drag-and-drop safety software supports you throughout design, verification, validation, and documentation.

TÜV-certified function blocks, predefined logic modules, and integrated simulations ensure faster project starts and safer results with minimal programming effort.

Your Benefit

Maximum safety with minimum effort. With samos® PLAN6, you reduce development time, avoid potential error sources, and accelerate the approval process of safety-related functions.

The license-free software speeds up commissioning and increases machine availability without compromising compliance or documentation quality.

SAMOS® PLAN6 – YOUR BENEFITS IN SAFETY PROGRAMMING

The six most important features compact, clear, and ready for your safety projects.

INTUITIVE OPERATION

Automatic hardware detection, drag-and-drop configuration, and a clean user interface make it easy to get started even without extensive prior knowledge.

🟢 Select features instead of writing complex code.

REAL-TIME SIMULATION

Test instead of trial-and-error: simulate your safety logic offline using fast-forward, slow-motion, or real-time including signal tracing and logic analysis.

🟢 Detect errors early without risking real equipment.

TÜV-CERTIFIED FUNCTION BLOCKS

Use an extensive library of certified safety function blocks, including emergency stop, muting, and two hand control, all built directly into samos PLAN6.

🟢 Reduces validation effort and speeds up implementation.

INCLUDES MOTION FUNCTIONS

Safe motion monitoring (SLS, SDI, SSR, etc.) without additional modules: six certified motion blocks for drives and conveyor systems including support for samos® PRO MOTION.

🟢 Ideal for machines with dynamic processes.

ONE-CLICK DOCUMENTATION

Generate complete safety documentation in a single click. Get project data, logic views, parts lists, SISTEMA values, and additional details, all compiled into a PDF.

🟢 Audit-proof, complete, and PDF-ready.

NO LICENSE, NO BARRIERS

Simply download and start: samos® PLAN6 is fully license-free and ready to use immediately.

🟢 No registration, no costs, maximum engineering freedom.

DISCOVER THE KEY SOFTWARE FEATURES

OF SAMOS® PLAN6

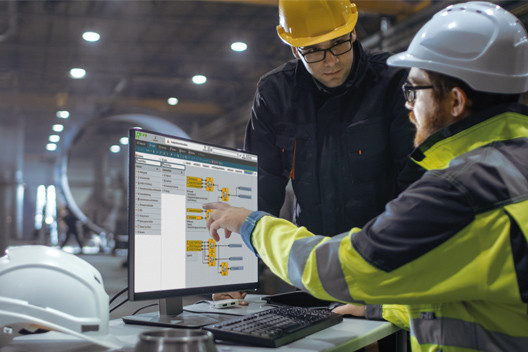

samos® PLAN6 is your powerful and intuitive development environment for safety logic from software programming to CE-compliant documentation. Every function is designed to help you work faster, safer, and in full compliance with applicable standards.

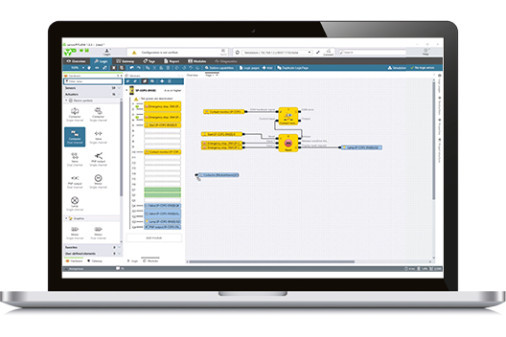

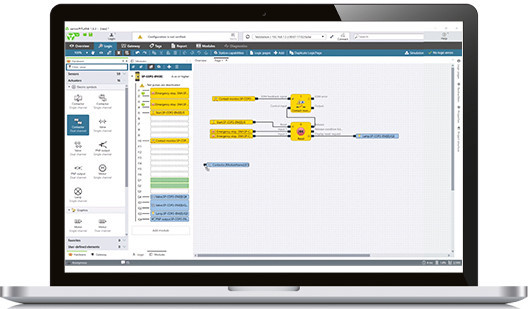

INTUITIVE CONFIGURATION – NO EXPERT KNOWLEDGE NEEDED

Get started without prior product knowledge: samos® PLAN6 automatically detects hardware and lets you configure safety logic on the fly using prebuilt function blocks. No need to select individual modules – just focus on what your application needs. Less effort, faster results.

AUTO ASSIGNMENT OF I/Os

Inputs and outputs are automatically assigned – ideal for SISTEMA-compliant documentation and faster validation. This saves time and helps avoid errors when creating matrix structures.

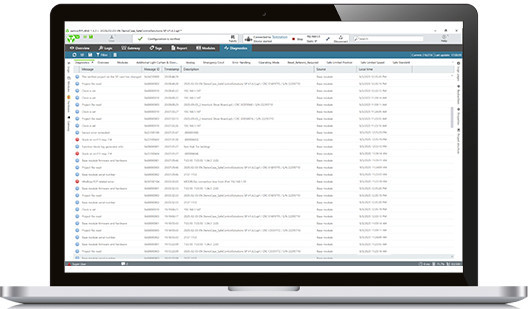

EARLY DETECTION OF FAULT CAUSES

With 4D diagnostics, detect EMC issues, bus errors or signal losses at an early stage – directly from the module in real time, including data export for further analysis.

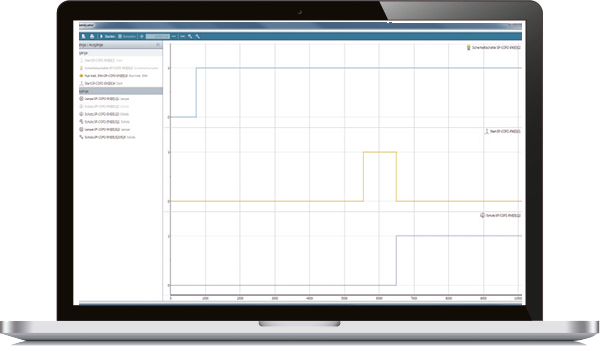

FASTER VALIDATION WITH OSCILLOSCOPE FUNCTION

Validate and verify safety functions directly on-site using the integrated oscilloscope view in online mode. Record signal behavior on a laptop, perform long-term analysis for troubleshooting, and export results as PDF for fast and compliant documentation.

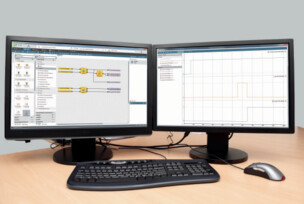

FLEXIBLE SCREENS

Arrange windows freely, work across multiple monitors, and save custom layouts to streamline your workspace – ideal for complex safety projects. You can also define your preferred start view (e.g. hardware or logic).

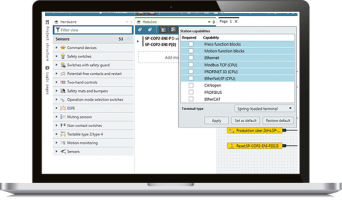

FAST MACHINE SETUP WITH FORCING

Set up your machine easily – even without connected sensors. Use the forcing function to simulate missing I/Os with a time limit of up to 8 hours. Automatic module detection suggests the right hardware for your logic – ideal for commissioning, testing, or shift changes.

PROTECTION AGAINST MANIPULATION AND UNAUTHORIZED ACCESS

Safeguard your machine against unauthorized changes and cyber threats. With project binding, the safety logic runs only on the assigned controller – and changes require the original project and a falsification code. SD card swaps and unverified Ethernet access are actively blocked.

GLOBAL REMOTE DIAGNOSTICS – FAST AND SECURE

Access your safety controller remotely via VPN, Ethernet, or mobile networks – for commissioning, troubleshooting, or support. samos® PLAN6 enables on-site diagnosis via LEDs, HMIs or PLCs, and connects you securely to the system – reducing downtime and avoiding costly service calls.

CONTEXT-SENSITIVE ASSISTANCE

The software provides context-sensitive help and assistants for each function. This shortens onboarding time and makes it easier to get started – especially with more complex projects.

SEE THE SAMOS® PLAN6 SAFETY SOFTWARE IN ACTION

These short demo videos give you a clear look at how intuitive it is to create and test safety functions with our software, making it the ideal entry point to your safety programming journey.

HOW TO GET STARTED WITH SAMOS® PLAN6

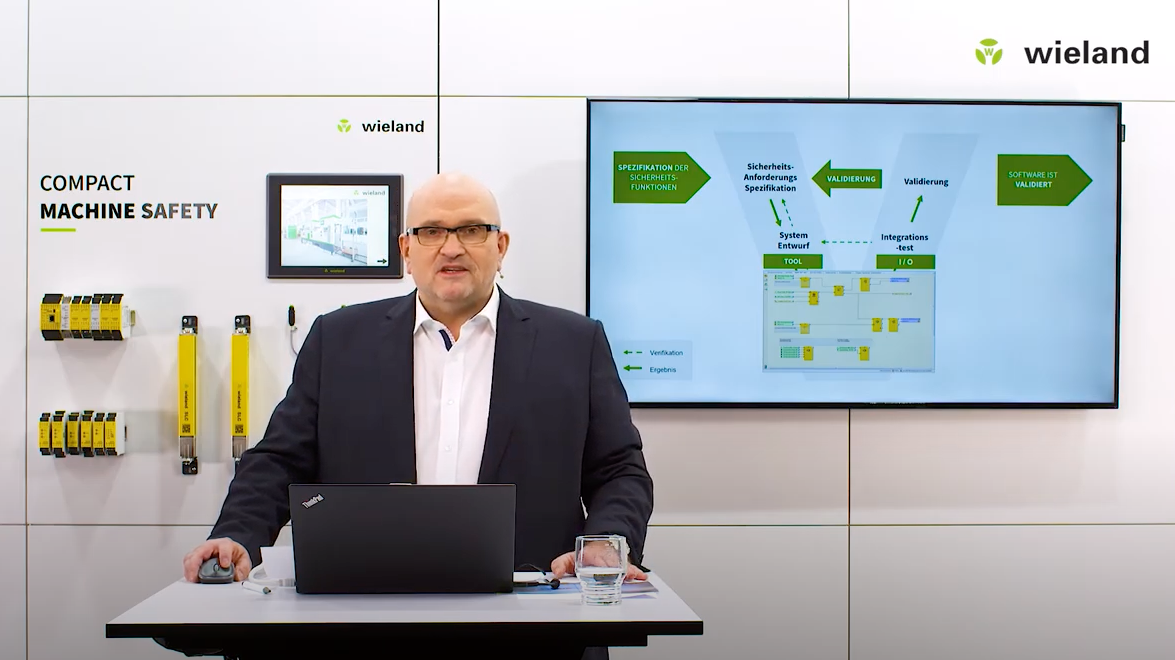

– SAFETY ENGINEERING STEP BY STEP

In this practical walkthrough, we show how to implement typical safety functions such as emergency stop, guard-door monitoring, or removal protection directly using samos® PLAN6.

You will also learn how the software automatically selects the appropriate hardware and how integrated tools for simulation, analysis, and documentation help you validate your safety application efficiently.

In this video you will explore:

- Creating a safety project following the V-model

- Graphical creation of safety functions (E-Stop, guard door, access protection)

- Simulation & logic analysis with timing control

- Forcing function for testing without connected sensors

- Automatically generated verification report including SISTEMA data

SAMOS® – FROM SAFETY PROGRAMMING TOOL

TO A FULL INTEGRATED SAFETY SYSTEM

With samos® PLAN6, your safety engineering process begins digitally and the corresponding hardware turns it into a fully deployable system.

Safety functions must be validated under real operating conditions to ensure reliable performance. That’s why the software is seamlessly integrated with:

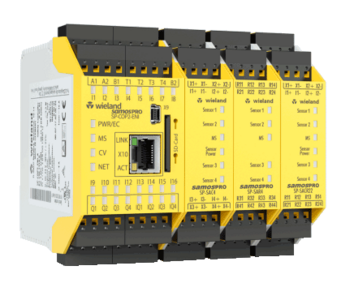

- the compact safety controller samos® PRO COMPACT

- the high-performance motion extension samos® PRO MOTION

Together, the intuitive samos® PLAN6 safety software and the samos® PRO safety controller form a scalable and certified safety system.

SAMOS® PRO COMPACT – INTELLIGENT SAFETY IN A COMPACT DESIGN

Compact safety controller with a width of only 45 mm perfect for safety-related control tasks in machine building.

SAMOS® PRO MOTION – MOTION CONTROL MEETS FUNCTIONAL SAFETY

The certified extension for motion-related safety functions such as SLS, SDI, or SSR seamlessly integrated into the samos® PLAN6 interface.

Now awarded “Product of the Year 2025” by Plant Engineering (USA).

SAMOS® Starter Kit:

The easiest way

to test & develop

You want to try out samos® PLAN6 live without a complex setup?

Then get started with the samos® PRO COMPACT Starter Kit:

- Safety CPU with Ethernet

- Connection cables & SD card

- Includes full version of the samos® PLAN6 software

- Ideal for testing, training, and proof-of-concepts

Simply download the software, connect, and start programming — plug & play into the world of safety.

FROM BASIC SETUP TO A FULL SAFETY ARCHITECTURE

MODULAR AND COMPATIBLE COMPONENTS – THAT SCALE TO ALL SYSTEM SIZE

ADDITIONAL RESOURCES & SERVICES

Discover our complementary offerings around samos® PLAN6

WHITEPAPER ON SAFETY PROGRAMMING:

Learn how to implement safety functions intuitively and in full compliance with standards using samos® PLAN6 — with concrete project examples and clear, illustrative screenshots. Perfect for a solid introduction.

Download Whitepaper

TRAINING FOR A SAFE START:

Learn in our hands-on training how to design, test, and document safety applications with samos® PLAN6 – step by step, directly on the system.

book a inhouse training

SUPPORT & SERVICES FOR YOUR APPLICATION:

Our safety engineers support you in implementing your safety projects in full compliance with the standards — from logic verification to CE-compliant documentation with samos® PLAN6.

request consultation

TECHNICAL DETAILS

- System Requirements: Windows 10 or higher (32- and 64-bit), .NET Framework 4.8 or later, approx. 150 MB of free disk space.

- Compatibility: samos® PLAN6 is suitable for all samos® PRO Compact controllers and fully compatible with the new samos® PRO MOTION series.

- Download Size: approx. 120 MB – installation wizard included in German/English.

SAMOS® MANUALS

Manuals: User manual, hardware documentation, and gateway guide available as PDFs.

Support: If you have any questions, our support team will be happy to help — just get in touch!

DOWNLOAD SAMOS® PLAN6 FOR FREE

Please fill out the form below to receive your free full version of samos® PLAN6.