- SEPTEMBER 2020

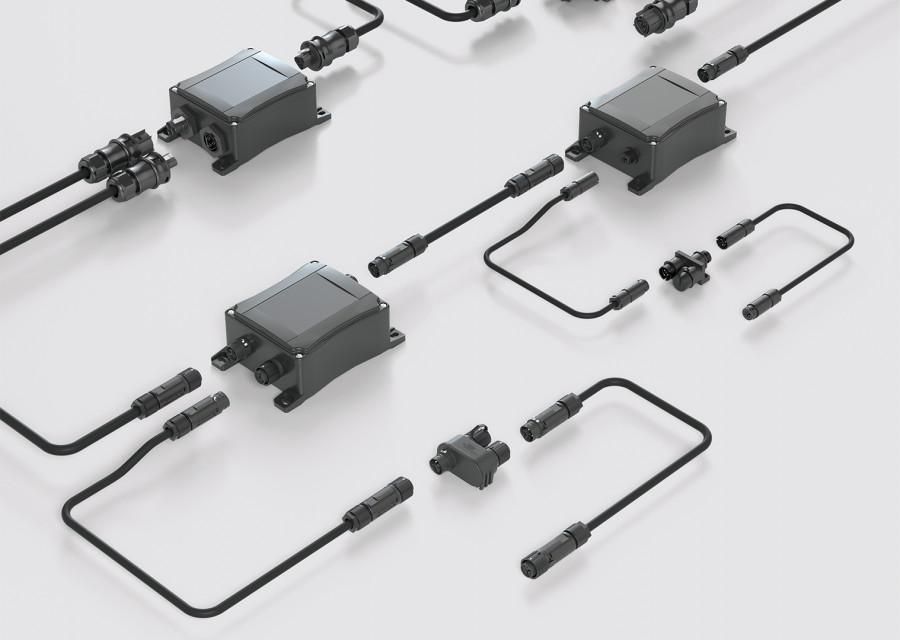

The RST® product family from Wieland enables smart pluggable electrical installation with the highest degree of protection

Parking garages, cold storage rooms, gardens – all these facilities have one thing in common: They are exposed to extreme stresses from the outside world and must therefore meet special requirements for electrification. Whether in the area of planning, design or implementation – the decisive factor is above all a safe, fast and simple implementation of electrical installation concepts. This applies in particular to requests for changes, expansion projects and temporary structures. The products of the RST® family from Wieland Electric not only guarantee rapid, error-free and flexible installation, but also a noticeable savings potential in terms of time and money. The RST® philosophy: a round plug connection, because "round" proves to be the optimal product shape to meet the highest safety standards and to protect the electrical installation system from disturbing environmental influences. Round, pluggable and flexible, that is: Ingeniously simple – simply ingenious!

The plug-in principle

Traditional cabling is characterized by time-consuming planning and installation processes, accompanied by annoying side effects such as unstructured cable routing and a lack of clarity in terms of material planning. With the completely pluggable, industrially prefabricated RST® systems from Wieland Electric, these challenges in power supply, distribution and device connection can be mastered. The main advantage of using RST® systems compared to conventional installation with junction boxes: Reduced error frequency and a decreased amount of work with approx. 70 percent time savings, because time-consuming connection work such as cutting the wires, baring and stripping the insulation is no longer necessary.

Safe and fast electrical installation for highest demands

Installers are more than ever dependent on being able to implement highly sophisticated electrical installation systems quickly and flexibly. The RST® family provides you with a comprehensive network of factory pre-assembled and carefully tested components of electrical connection technology, which provides a universal pluggable and safe solution from the distribution unit to every point of use. The RST® plug connections also open up new optimization potentials in areas that are exposed to extreme environmental influences, e.g. energy supply (solar panels, balcony solar power plants), demanding functional areas (e.g. commercial kitchens, laboratories, greenhouses, other damp areas) or areas of application that have sensitive interfaces between indoor and outdoor areas (e.g. agriculture, maritime applications such as shipbuilding, alpine facilities such as gondolas, lifts).

The RST® family: robust and versatile

Electrotechnical applications that are not only located within a building must function faultlessly under difficult conditions and guarantee the highest level of safety – and this over many years. The penetration of moisture or foreign bodies (e.g. dust, oil, soot) in outdoor areas (e.g. parks, garages) would definitely mean the end of the system. This is where the RST® principle comes into play: The round pluggable installation systems are designed to provide above-average protection against environmental influences. They can even withstand strong jets of water or unplanned immersion or submersion.

The RST® POWER series is particularly aimed at device construction. With a current-carrying capacity of 50A and an extremely compact design, the high-current connector scores particularly well in the installation of solar and building power systems.

Applications that require a higher IP protection class (e.g. luminaires, motors, heat pumps, power supply units) can be equipped with the all-rounder RST® Classic (250 V, 250/400 V, 20-25 A) and the compact RST® Mini (250 V, 250/400 V, 16 A) connector system with IP66/68/69 protection. Both systems are approved according to IEC 61535 and have cULus certification, which allows the connector system to be used in North America. In order to optimally implement the increased safety requirements, the components are delivered pre-assembled to the construction site, thus avoiding unnecessary and error-prone additional work. While RST® Classic, with the largest product portfolio, guarantees above all a high degree of flexibility in the distribution of current and signals, RST® Mini, with its optimized size and design, helps to realize this in the tightest installation conditions.

Applications in the low-voltage range, which are designed for a current of 8 amperes and where the electrical installation must be planned above all in an extremely space-saving manner, can in future be equipped with the RST® Micro (250/400 V, 8 A) system. The advantage: The miniature connector RST® Micro is therefore also suitable for network application. RST® Micro is currently designed with 2/3 poles, however, the connector system will be expanded and optimized in the future.

PRESS CONTACT

WIELAND ELECTRIC GMBH

Marketing Communication

Alexander Viertmann

Communications Manager

Brennerstraße 10 – 14

96052 Bamberg · Germany

E-Mail: communications@wieland-electric.com

Phone: +49 (951) 9324 - 316